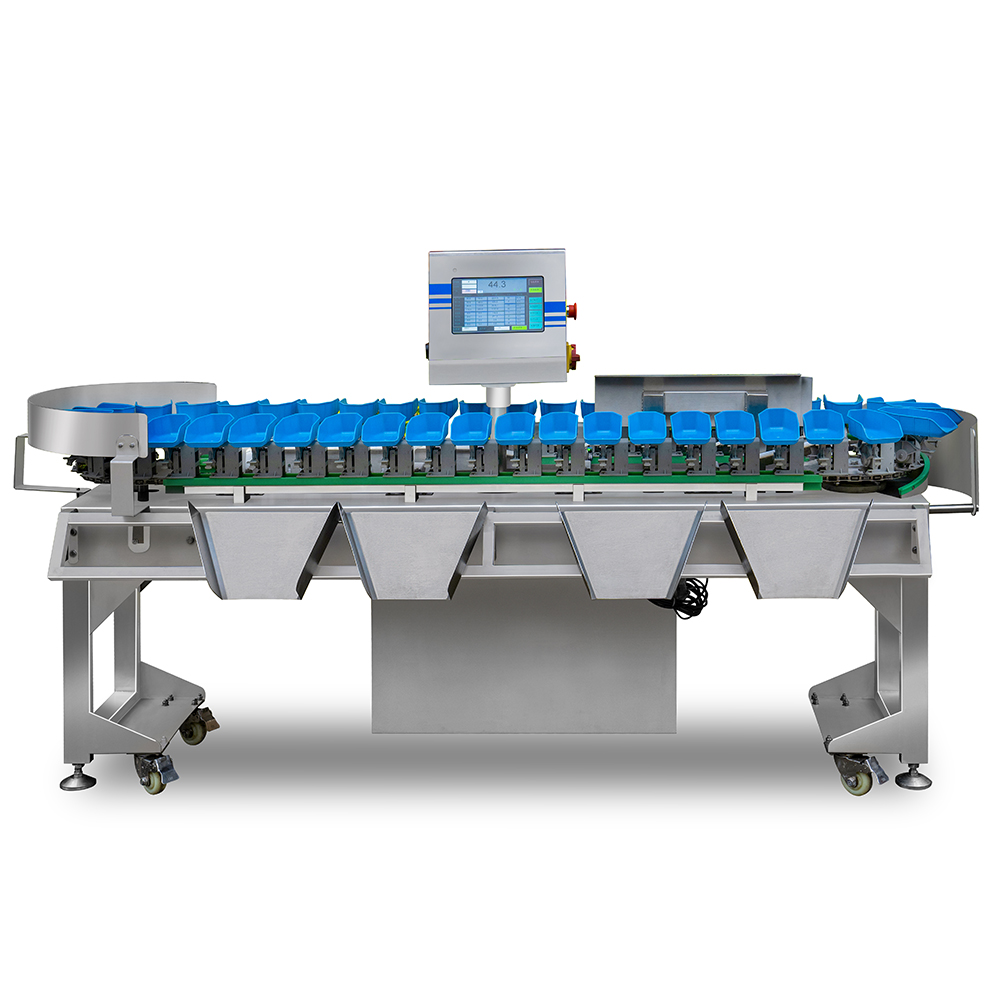

Marine pollution has been increasing in recent years. Therefore, the difficulty of farming seafood has increased. But consumer demand is still rising. People are concerned about the quality of seafood (sea urchin, seaweed, sea cucumber, oyster, abalone, caviar, etc). So grading and detecting seafood products are necessary for seafood processors. Weight sorting machine can increase effcient for your seafood processing production.

Abalone

Caviar

Kelp

Oyster

Sea Cucumber

Sea Urchin