Precision Checkweigher Systems for Accurate Weighing Solutions

Boost your production efficiency with our high-performance inline checkweighers. Ensure product quality and compliance with Easyweigh’s advanced checkweighing technology.

What is a Checkweigher

A checkweigher is a crucial tool for ensuring the accuracy and consistency of your products. Whether in food production, pharmaceuticals, or manufacturing, our checkweigher machines help you comply with regulatory standards, reduce waste, and enhance efficiency. Easyweigh offers a variety of checkweighers, all designed to fit seamlessly into your production line.

Explore Our Checkweigher Solutions

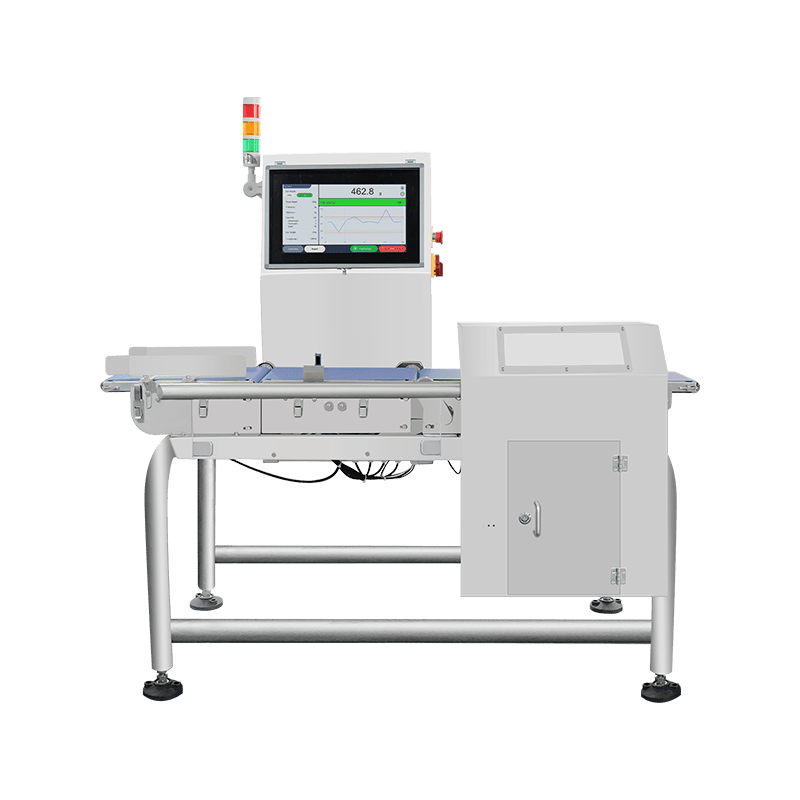

Checkweigher PC Series

Checkweigher PC Series automatically verify the weight of packaged food, ensuring it meets specified ranges and rejecting those that don’t. Widely used in food, pharmaceuticals, agriculture, and cosmetics, this versatile checkweigher provides reliable results for quality and regulatory compliance.

- Self-learning function

- Remote control

- Accuracy: ±0.1g

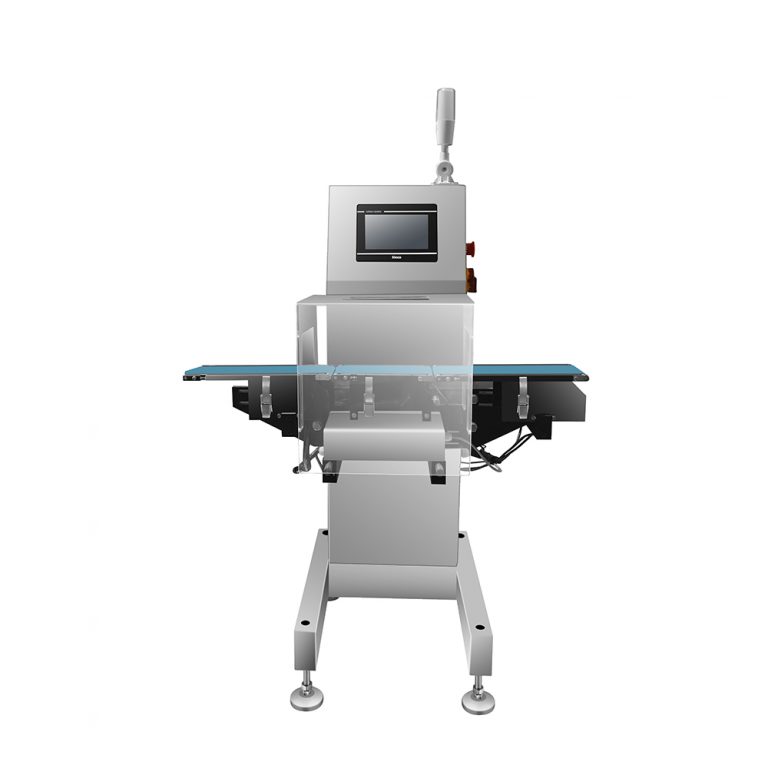

High Speed & Accuracy Checkweigher

High-speed checkweigher machine designed to detect small-weight packages and identify unqualified items, it excels in various industries such as food, pharmaceutical, agriculture, and cosmetics. Easily detect overweight or defective products like powders, liquids, and tablets.

- Accuracy of up to ±0.1g

- User-Friendly Interface

- Checking Range: ≤50g

General Purpose Dynamic Checkweigher

Easyweigh General Purpose Dynamic Checkweigher ensures product quality. It verifies product weight and detects missing parts in various industries (snacks, poultry, fish, seafood, fruit, etc) The dynamic checkweigher is suitable for most production requirements.

- Accuracy:±0.3g ~ ±1g

- Working Speed: 20~90m/min

- Customizable reject devices

Checkweigher PC Series

Heavy-weight Checkweighers are designed for precise detection of large packages. They easily identify shortages, overweight, and missing items in boxes. Easyweigh checkweigher ensures accurate weight detection during production. With a capacity of up to 60kg, it’s the ideal solution for efficient quality control.

- Accuracy:±5g ~ ±50g

- Minimum Scale: 5g

- Working Speed: 15~35m/min

Key Benefits of Easyweigh Checkweighers

Accuracy

Easyweigh checkweigher systems provide precise weight measurements with an accuracy of up to ±0.1g, which helps reduce errors and enhance product quality.

Efficiency

Inline checkweighers optimize your production process by saving time and resources. They can also avoid weight mistakes in the manual method.

Compliance

Easyweigh checkweighing technology ensures compliance and quality control. Meet strict industry regulations effortlessly.

Integration

Our in line checkweigher can be easily integrated with other inspection equipment, we have a solution for every need and optimize production efficiency.

Industries That Benefit from Checkweigher Machines

About Easyweigh

Guangdong Easyweigh Equipment Co., Ltd, based in Zhongshan within the Guangdong-Hong Kong-Macao Greater Bay, specializes in developing and manufacturing inspection systems and sorting machines in China. We operate a factory in Zhongshan and R&D offices in Shenzhen. Our products are available in over 150 countries. We hold 27 patents and 13 software patents, have received CE and FDA certifications, and were recognized as a high-tech enterprise by the local government in 2016.

Our Amazing Clients

FAQs about Checkweigher

What is a Checkweigher and How Does It Work?

A checkweigher is an automated weighing system. It ensures products meet precise weight specifications. Products move along a conveyor belt, and the checkweigher system measures their weight in real time. If a product is underweight or overweight, it is automatically rejected using pushers, air jets, or diverters. Checkweighing helps ensure compliance with weight regulations and improves product consistency.

What Are the Benefits of Using a Checkweigher Machine?

- Ensures compliance with various industry regulations

- Reduces product giveaway and minimizes waste

- Enhances production efficiency with real-time monitoring

- Integrates with metal detectors & X-ray systems for complete inspection

What Factors Should I Consider When Choosing a Checkweigher?

- Product Size and Weight Range: Ensure the checkweigher can accommodate your specific product dimensions and weight.

- Weighing Speed and Accuracy: Choose a checkweigher that meets your production volume and accuracy requirements.

- Integration Capability: Verify that the machine can seamlessly work with your existing conveyor systems.

- Reject Mechanism: Depending on the type of product, select from options like pushers, air jets, or drop.

- Compliance Requirements: If you're in the food or pharmaceutical industries, ensure the checkweigher meets relevant standards, such as HACCP, BRC, or FDA approval.

View More Checkweigher Solution

We will respose in 24 hours and provide you the best checkweigher solutions for your products.