Introduction

X-ray inspection systems and metal detectors are two devices for product inspection services, ensuring safety and industry compliance. However, the X-ray inspection machine is usually more expensive than the metal detection technologies, even with the recent advancements the latter has experienced. It begs the question, “why?”

Find the answer to this question, among other intricate details, on X-ray inspection systems and metal detectors. Read ahead!

Why Do X-Ray Inspection Systems Cost More Than Metal Detectors?

X-ray inspection systems cost more than metal detectors mainly for two reasons. First, X-rays operate with a more sophisticated and advanced technology, and the other is because of the higher manufacturing cost of a typical X-ray detector. Below, we will expand on these two primary reasons why an X-ray detector is more expensive.

Working Mechanism Complexity in Technology

As mentioned earlier, X-ray detectors are a more advanced tech, operating based on a more intricate tech than metal detectors. Generally, X-ray inspection systems work on the principle of radiation penetration. The device releases energy (photons) through X-rays, transported as radiation easily noticed electronically or visually. The detector material absorbs this photon, resulting in ionization – energy transfer – creating advanced detailed images, enabling identification.

On the other hand, metal detectors function on the principle of electromagnetism. When a metallic object passes through the detector, there is a distortion in the electromagnetic field, which the device responds to by raising an alarm. Therefore, the operator understands that metal is present in the material.

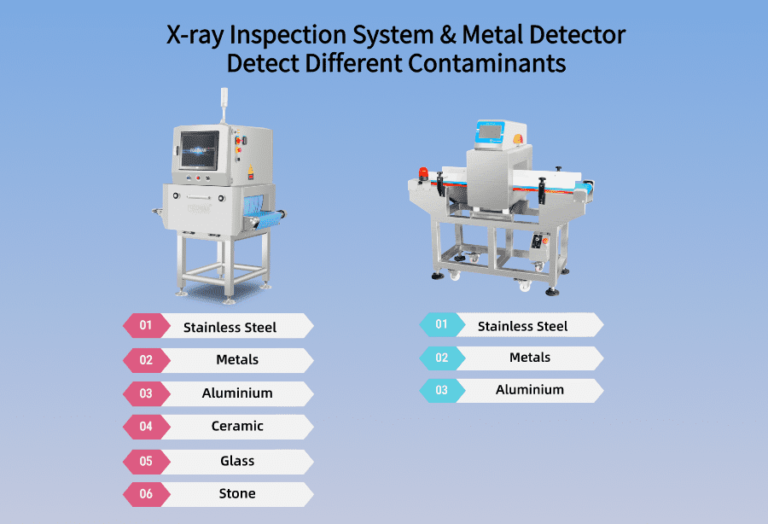

Now that you understand the working principles of both devices, you’d agree that X-ray detectors are more complex, accounting for the higher price of the X-ray inspection machine. As the radiation passes through the object, it evaluates the material’s density, size, and composition. It then creates images that allow more credible and effective identification of diverse materials, including plastics, ceramics, and other contaminants. Metal detectors generally struggle to detect non-metals, which is a significant limitation of the device.

Higher Manufacturing Cost of X-Ray Inspection Machine

Since X-ray inspection systems are more sophisticated, the manufacturing costs for their components are also more expensive. These components, particularly the x-ray tube, detectors, and some specialized software that enable the action of this device, acquire higher manufacturing costs than those of metal detectors.

- X-ray Light Tubes: X-ray detection systems use specialized X-ray tubes to generate controlled beams of X-rays. These tubes are high-precision instruments requiring sophisticated tech and high-quality materials for manufacturing them.

- The Detectors: X-ray inspection systems use highly sensitive detectors that capture detailed images of the detecting material. The manufacturing of these components is also delicate, requiring advanced tech.

- Software: The software that interprets the X-ray-generated images is crucial to this inspection system’s overall functioning. The software allows the device to handle diverse material types and provide detailed analysis of the detecting material. Therefore, it must be sophisticated, which accounts for the increased costs of this system.

- Other Components: Other components like shielding materials, conveyor systems, and structural elements also require high-quality materials with high-precision manufacturing processes to meet industry standards.

On the other hand, metal detectors also consist of intricate components like the coil and the sensor technology it operates on. However, most of these parts require more straightforward construction and technology, making it a more cost-effective detection system. Therefore, while X-ray inspection systems are complex, metal detectors are more concise, working on a more straightforward principle that focuses on detecting the presence of metal in the detecting material.

Why Consider X-ray Inspection Instead of Metal Detector?

Numerous advantages make it advisable to consider X-ray inspection over metal detectors. A typical reason to consider X-ray inspection systems over metal detectors is the extensive range of materials they can detect, including metals and even organic substances.

Below, we discuss other reasons to consider X-ray inspection over metal detectors.

In-depth Analysis of X-Ray Technology

As mentioned earlier, X-ray inspection systems offer more sophisticated and in-depth analysis. This device excels in identifying a vast range of materials beyond metals. This feature makes food X-ray machines more beneficial for detecting contaminants and impurities, enhancing products and food safety.

Resolution and Image Clarity of X-Ray Inspection Machine

X-ray inspection systems produce high-resolution images, which prove vital as they provide comprehensive views of the internal structures within the detecting material. This feature mainly benefits quality control analysis, where manufacturers have to access the intricate components in a product, particularly food and pharmaceuticals, that significantly depend on high precision and accuracy. It helps them verify the product’s integrity and validate it as good enough for human consumption. This feature is unavailable in metal detectors, as you do not have a visual view of the contaminants or the impurities in the detecting material.

Durability

Since X-ray inspection systems use high-quality materials for their fabrication, coupled with advanced software and manufacturing techniques, the device is generally more durable than metal detectors. This is another valuable reason to consider X-ray inspection systems over metal detectors, as you are assured of using the device for extended periods.

Different Ability for Foreign Objects Detection

Unlike metal detectors, X-ray inspection systems can differentiate between different materials and foreign substances in the detecting material. For example, food metal detectors will only detect metal objects in food substances; they will be ineffective against complex compositions containing diverse material options.

On the other hand, food X-ray inspection offers a valuable advantage, possessing more advanced sensors that allow it to detect an extensive range of contaminants. The device provides superior inspection capabilities, making it a better choice for non-metallic and foreign object detection.

Situations That Use Both X-ray Inspection And Metal Detector

We have already emphasized that X-ray inspection systems are more effective than metal detectors. However, many manufacturing industries may combine both devices to improve inspection outcomes, guaranteeing product safety.

Below are situations where both devices are used.

- Quality Assurance in the Food Industry: X-ray inspection and metal detectors help ensure comprehensive safety. It provides insights that may prove beneficial in ascertaining that a product lacks metallic contaminants or foreign objects.

- Pharmaceutical Product Inspection: Most pharmaceuticals are delicate substances devoid of contaminants or impurities, considering these substances interact with bodily fluids. Therefore, the dual approach of metal detectors and X-ray inspection systems will prove crucial in guaranteeing quality control and ensuring the product meets strict pharmaceutical standards.

- Industrial Manufacturing Quality Control: Industries manufacturing complex products like electronics and consumer goods utilize both technologies. The metal detectors help them spot metallic defects during parts fabrication and processing, while the X-ray system will also help note faults from non-metallic objects.

Besides these situations, both technologies may also prove effective in the following:

- Customs and border control

- Verification of Product Packaging:

- Recycling facilities

- Research and new product development purposes, etc.

Market Trends and Demand for X-Ray Inspection Machine

Even with higher costs, X-ray inspection systems are gaining popularity and will soon take over the inspection and detection world. Below, we enumerate the market trends for this device.

Growing Demand for X-ray Inspection

There’s already a growing demand for X-ray inspection because of the superior inspection compared to other devices like metal detectors. Therefore, companies that deal in diverse products, particularly those made of non-metals, require X-ray inspection for quality control analysis. Moreover, the need to meet up with regulatory standards requires them to use advanced tech like those X-ray inspection machines provide to comply with industry requirements.

Sustained Role of Metal Detectors

Over the years, metal detectors have been relegated to use for security purposes. However, due to technological advancements, it is observed that these devices can offer much more, particularly in the areas of detecting metallic contaminants and impurities in foods and other sensitive products. Therefore, there’s a rise in the demand for X-ray inspection devices for different purposes, especially in manufacturing industries.

Market Forces Influencing Costs

Market forces influencing the costs of X-ray inspection systems include supply chain disruptions and technological advancements. Disruptions in supply chains globally, such as during major geopolitical events or the last pandemic, can elevate the costs of these gadgets. Also, ongoing technological advancements and increases in research lead to innovations that help create new features in these inspection systems, which may further elevate the price.

Test X-Ray Inspection For Free

Customers willing to test their product through our X-ray inspection system can do that for free. We offer premium X-ray inspection for your samples, providing you with the most suitable X-ray inspection system.

However, it is imperative that customers first confirm whether their product supports this testing or not. After doing this, you can send the samples to us, which we will help you test and give you a comprehensive report for free.

Our facilities have next-generation X-ray inspection systems, including metal detectors and other inspection devices. We guarantee high-quality services, ensuring your product meets all necessary industry standards and regulations.

Contact us today!

FAQs

A. What Makes X-Ray Systems More Expensive Than Metal Detectors?

X-ray systems are more expensive than metal detectors because of the advanced tech and software that form the basis of their superior functionality. Also, it uses high-quality and more sophisticated materials in the manufacturing of components of this device. All these together account for the X-ray system’s higher manufacturing and development cost, making it more expensive than metal detectors.

B. Are There Scenarios Where Metal Detectors Are More Cost-effective?

Yes, metal detectors are a more cost-effective option, mainly when detecting metallic components in a material. The device quickly detects the presence of metals in the detecting material without requiring comprehensive imagining. Consequently, they are the go-to choice in security screening, where identifying metal objects is the goal, and there is less worry about other complex materials.

C. How Do Regulatory Standards Impact the Cost of Inspection Systems?

The need to meet stringent regulatory standards adds to the overall manufacturing costs of inspection systems. The materials and manufacturing methods must adhere to the quality standards and safety requirements. Therefore, manufacturing companies must use the most appropriate materials and maintain the standard at every production level, resulting in elevated production costs.

D. What Advancements Can be Expected in Cost-effective Inspection Technologies?

Advancements in cost-effective inspection technologies should focus on streamlining the manufacturing processes. This will prove effective in limiting production costs. Other possible advances may improve the software’s efficiency, including the sensors and detectors’ sensitivity, which will also help streamline the inspection process.

Conclusion

X-ray inspection systems are costlier than metal detection because they’re more advanced. That’s the simple reason. The device utilized more sophisticated materials, software, and detectors that help ensure more accurate inspection services. Moreover, it provides a comprehensive imaging of the detecting material, providing more detailed information.

Whether you are using it for food processing, quality control, security, pharmaceutical product inspections, research and development, etc., it offers superior services to metal detectors. Also, it’s capable of detecting metallic contaminants in these products.