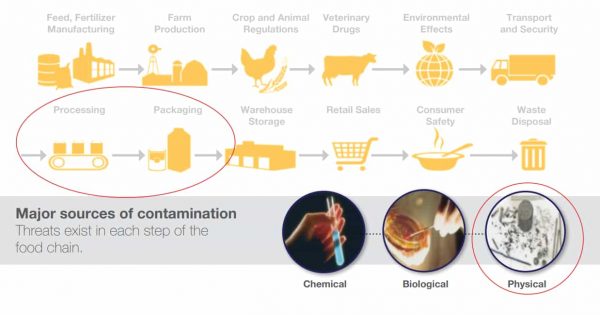

Food x-ray inspection is a conventional strategy for the food industry nowadays in the movement against contaminants in food processing. Food safety is the primary responsibility of food producers, as products are susceptible to various contaminants. Food inspection and safety comprises analyzing biological, chemical, and physical hazards in food manufacturing.

Nevertheless, X-ray food inspection is a widely embraced idea for ensuring food safety. This article discusses in detail why you should choose x-ray machines for your food and beverage industry, how x-ray machines work, factors that affect x-ray machines, and how to select an efficient x-ray machine.

Growing Problems Threat to Food Supply Chain

The growing problem of food threats in the food supply has been a primary concern to various producers. Although chemical and bacterial food contaminants have earned more attention in the food industry, foreign bodies have been the prominent contaminant in packaged food and beverages in the past years.

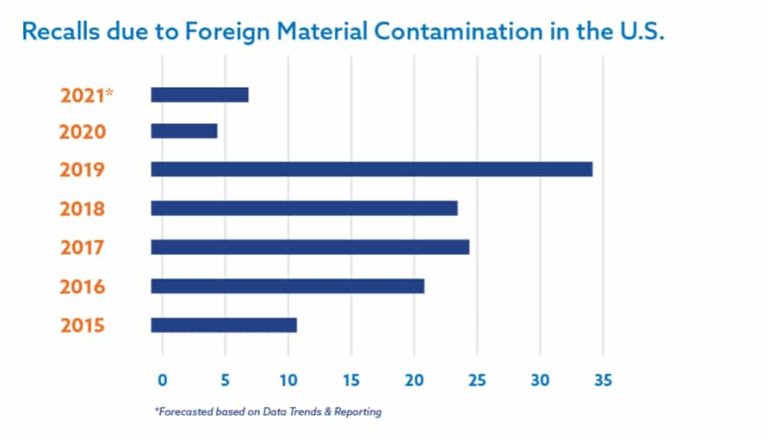

Despite this unending attention, the physical contaminants problem continues to threaten food safety in the food supply chain. According to the USDA Food Safety and Inspection Service, in 2016, 11 percent of the total food recalls were due to extraneous substances. A year after, 43 percent of the recalls reported by the FSIS resulted from foreign bodies – approximately a 291 percent increase compared to 2016.

These threats typically exist in each step of the chain, and these food contaminants can cause food-related injury or death to consumers. Therefore, you need to use a food x-ray inspection system to systematically detect any possible foreign objects in your packaged beverages or food items before sending them to consumers.

Strict regulatory standards of food safety have resulted in many foods recalls. Consequently, most food manufacturers, processors, and distributors have suffered a recall. These recalls are usually higher than any industry can bear as food producers pay a heavy price as a sanction for food recall. A food company pays about $10 million in direct costs for food recall.

According to the Food Safety and Inspection of the USDA report in 2020, about 48% of foods were recalled for contamination. The primary factors attributed to the recent recalls include food production and monitoring process inadequacies. The U.S FDA 2017 archive list of recalls shows the following causes:

- Presence of Metal

- Foreign Object (rubber)

- Small pieces of plastics

- Contain glass particles

Some specific laws and regulations ensure food safety worldwide. Some of these laws and regulations include

- HACCP – Hazard Analysis and Critical Control points

- IFS – International Food Safety

- GFSI – Global Food Safety Initiative

- ISO – International Standard Organization

They usually include compliance requirements and better restrain producers as they prevent food hazards. As a result, food producers use food x-ray machines to detect foreign items ensuring that all food regulatory and safety standards are fulfilled. Consequently, food businesses thrive more from dynamic inspection programs and gain confidence in complying with all regulations.

Advantage Technology Update

The safety of food items has been a primary concern for consumers since the industrialization of food processing. There are several sources of contaminants from machines in the processing line – cutting blades, nuts, and rubber gaskets. The more processed foods like beverages find their way to the market, the more contaminants risk.

Over the past decades, X-ray inspection systems have been a reliable technology for detecting various threats in food manufacturing. As technology advances, its costs reduce. As a result, food producers have varying choices in their approach to food safety options. The advent of x-ray machines as an offline service offers the perfect advantage to inline food inspection capabilities.

X-ray machines operate at moderate speed with different power supplies allowing them to find the tiniest contaminants with 0.2mm or smaller. Consequently, the x-ray machine is much better and more reliable than metal detectors because it detects metallic contaminants. Metallic packaging does not affect metal detection and is immune to environmental factors.

The x-ray inspection systems detect varieties of physical contaminants. Although metal is its major contaminant source, it is not the only quality control hazard. Other contaminants such as glass, rubber, stone, bone, and more exist because of the food type, raw material source, or manufacturing processes.

X-ray inspection machines are advanced equipment that can distinguish between contaminants and abnormalities, such as metal retaining clips or packaging errors. These x-rays can handle different products, from cans and bottles to meat and bulk food items. Most food producers depend on x-ray machines to ensure that their products meet the high standards of their brand because it offers excellent efficiency and accuracy.

Working Principle of Food X-Ray Inspection

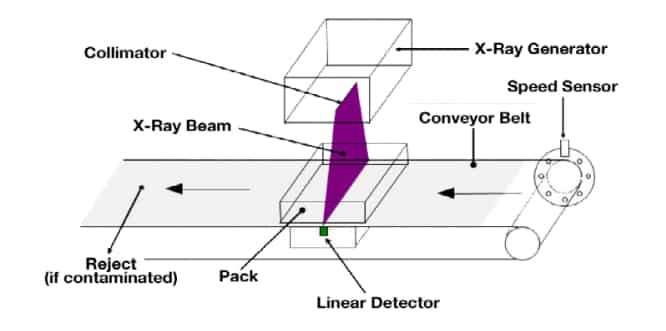

The effectiveness of an x-ray machine depends on the sophistication of its data analysis. X-ray inspection machines operate on the density difference between the product and the food contaminant. It loses some electrons whenever the x-ray penetrates products on the production line. Dense areas like contaminants reduce the energy even more.

However, as the stream of X-rays leaves the product, it gets to a photodiode sensor. This sensor changes the energy signal into a grey-scale image of the internal content of the processed food product. The machine indicates foreign bodies a darker shade of grey than the product.

How X-Ray Inspection Systems Work in Production Line

The x-ray inspection system penetrates solid products using high energy, which can be channeled into a radiograph. The work of the radiograph is to show you things that are not supposed to be present in the scanned product, along with its precise location in the package. The density of the material being scanned determines the color of the radiograph image.

As a result, if the image appears lighter, there is a less dense object in the product. Lighter images make it easier to analyze a product’s real-time analysis and quickly identify the anomaly within a product. In addition, x-ray machines can identify incomplete or missing products and low mass levels.

You must note that you can use x-ray machines at any point in your production line. It can be during the sorting stage or as a part of the final checks before packaging your products. You can use x-ray machines with check weighers, metal detectors, and conveyor systems. This integration allows you to form a comprehensive central inspection in your production line.

Regular maintenance of your x-ray machine will help maintain your process’s accuracy and longevity and lower inspection costs in the long run. It gives you a better chance at conducting a real-time data analysis of your products. Remember that when you integrate an x-ray machine into your production line, you need a Radiation Protection Supervisor in compliance with ionizing radiation regulations.

However, most x-ray machines have data logging of the rejected products in the production line. As a result, you will be notified of errors and get detailed information about the causes. It allows you to prevent future occurrences while it helps to audit, reduce waste and increase productivity.

Capacities and Types of Foreign Objects that Can Be Detected

X-ray machines have a dependable detection capacity reason being that they can identify a large number of contaminants in the food production line. When other inspection means, such as metal detection, are limited to a specific contaminant type, x-ray systems allow you to detect varieties of impurities in food material.

Thus, x-ray inspection systems are ideal for several applications within the food industry, ranging from granulated products to frozen food and manufacturing. Some of the foreign objects that an x-ray machine detects include;

- Missing products

- Produce clumps

- Metal

- Non-ferrous metals in foil, such as stainless steel

- Bones

- Plastics (Teflon)

- PVC plastic

- Stone or concrete

- Flavor or sugar clumps

What Factors Affect X-ray Inspection Sensitivity?

The following factors may affect how effective the sensitivity of an X-ray inspection system will be:

Product Density and Thickness

Always use an x-ray inspection system for thin, lightweight, and similar products when packaging your food. It would help to note that high-density and highly textured products reduce performance. However, it would help to note some low-density materials, such as insects, paper, and cardboard, that the x-ray machines won’t detect. As a result, you should consider programming your x-ray inspection system to scan through the least material in your production line.

Detection Environment

The detection environment of the contaminants typically comprises its temperature or humidity, which may affect the working conditions of the x-ray. It may affect the image representation of the scans.

Line Speed

The performance of an x-ray system can reduce at an extremely high speed. As a result, it is best to scan through your packages slowly to have a better chance of detecting contaminants effectively.

Hardware and Software Configuration

You need varying algorithms to find irregularities or anomalies. Different algorithms give you a better chance of getting a more transparent x-ray detection pixel. The x-ray detector’s pixel size may limit the imaging or sensitivity of an x-ray. Also, larger x-ray detector pixel helps reduce image file size and scanning time.

Are X-Ray Inspections Safe?

Food x-ray inspection equipment uses high-voltage x-ray tubes to create images instead of using radioactive materials. They are safe to use as they do not harm food or the operator as there are no radiation leakages. If the tube is off, it emits no form of x-ray energy. The food in the production line usually spends a little time under the x-ray beam. It receives a minimal dose of radiation exposure to the food at the time. Nowadays, x-ray systems are more efficient and operate at more than 70 percent lower wattage than archaic systems.

The U.S food and drug Administration proved that x-ray systems have no side effects on the food supply, nor does it affect the flavor, taste, or nutritional value of the inspected food items. Likewise, a study conducted by the World Health Organization proves that food items can be exposed to more than 600 million x-ray scans without reducing their quality or safety.

What Are the Differences Between Metal Detectors and X-Ray Inspection Systems

| Feature | Metal Detector | X-Ray Inspection System |

|---|---|---|

| Detectable Materials | Detects metals like wires and aluminum. | It detects metallic objects and many other solid contaminants. |

| Accuracy | The accuracy of metal detectors is 0.8 | It can detect metals and other contaminants with an accuracy of 0.3. |

| Speed | The speed is 32m/min. | The conveyor speed is 10-70m/min. |

| Sensitivity | It has the best sensitivity for small products, unpackaged products, dry products, or products with non-conducive packages. | It is more sensitive to packaged products like metal cans and glass bottles. It is also suitable for metalized seals or film. |

| Performance Requirements | Performance depends on product effect, aperture size, and software. | Its performance depends on X-ray power, product texture, receiver, and software. |

| Pricing | More affordable than x-ray inspection system. | X-ray inspection systems are 2 to 3 times more expensive than metal detectors. |

| Challenges | Conductive products such as wet or salty goods are often challenging. | It has challenges performing well with tender or dense products with lots of texture. |

What kind of contaminants can be detected?

| Detectable Contaminants | Metal Detector | X-ray Inspection System | Comment |

|---|---|---|---|

| Non-ferrous metal | Easy | Easy | can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. |

| Ferrous metal | Easy | Easy | Calcifed bone can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. |

| Stainless steel | Harder | Easy | Calcifed bone can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. |

| Aluminum | Harder | Harder | Calcifed bone can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. |

| Wires | Harder | Harder | Calcifed bone can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. |

| Glass | Harder | Calcifed bone can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. | |

| Stone | Harder | Calcifed bone can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. | |

| Bone | Difficulty | Calcifed bone can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. | |

| Rubber, Plastic, Wood, etc | Difficulty | Calcifed bone can be detected by x-ray inspection system. Products size and density affect the accuracy of food x-ray machine. |

Most food producers now take a keen interest in integrating x-ray technology into their food production stages purposefully to detect contaminants of different forms. Although the X-ray inspection systems are effective and reliable in identifying foreign material, there is a need to consider these priorities in selecting an efficient x-ray inspection system:

Conformity

Choose an inspection system that makes it easy and possible to fulfill all mandatory food safety standards and regulations. The machine should be sensitive to detect foreign materials as small as 0.3 mm.

Thus, it prevents all physical food contamination while upholding all legal requirements and third-party standards for food safety. In addition, it should operate consistently with high detection accuracy levels necessary for the risks.

Safety and Hygiene

The x-ray inspection system must protect operators, data, products, and the brand. The x-ray machine must safeguard consumers and ensure traceability while limiting exposure to radiation for the operators and the products. Asides from protecting the consumers, the x-ray machine must be able to offer the company other quality benefits.

In addition, the x-ray machine must be designed to avoid cross-contamination like every other food processing equipment. It must possess a decent hygiene design that makes it easy to clean, wear-resistant, and many other things.

Operation

The x-ray system for food inspection must be straightforward to operate by anyone to avoid risks of human error. Setting up a new x-ray machine for the first time is often complicated. Thus, it is advisable to let an expert handle the initial setup.

Nevertheless, it should be accessible and useable by all relevant employees irrespective of the level. The controls and functionality must be simple to prevent errors and reduce the operation time. In addition, the x-ray should possess software with a flexible detection capacity and other quality control benefits.

Service

The manufacturer of the x-ray system should provide comprehensive service and support to ensure the continuous performance of the system. Throughout the x-ray system’s lifecycle, the manufacturer should give consistent servicing, ensuring that the machine functions correctly.

We have various modern x-ray inspection systems with the most intuitive functionality depending on your operational and application demands. Our x-ray machines offer advanced inspection capabilities for widespread quality problems such as under-and over-fills and missing pieces and components.

For instance, our x-ray inspection system for unpackaged bulk products detects food contaminants with high stability and accuracy. It is suitable for inspecting unpackaged and loose products like nuts, flour, rice, oatmeal, candy, etc.

Likewise, our x-ray inspection system for canned products also effectively detects contaminants like bones, glass, metal, stones, rubber, etc. It can also detect missing parts or defective products. Its special design makes it suitable for cans, vertical boxes, paper boxes, or paper bags.

These products have several features in common, including the following:

- High accuracy and efficiency

- More specialized detection

- Improved detection range

- Safety and reliability

- Auto-Learn feature

- Intuitive operation interface

- Better configuration and stability

Conclusion

The x-ray inspection system is a reliable first-line contaminants detection system that helps to safeguard consumers and producers in the food industry. It is essential to know that the x-ray inspection system detects beyond metal fragments. It detects other physical contaminants such as stone, glass shards, and plastics. To get the best inspection results from the x-ray inspection system, you need to pay more attention to its working capacity and the factors that affect its sensitivity.