Introduction

As consumer demand for safe, high-quality meat products continues to rise, ensuring that every product is free from harmful contaminants has never been more important. Maintaining stringent safety measures is essential from farm to fork, and X-ray inspection systems have become a game-changer in the meat processing industry.

Contaminants such as bones, metal fragments, and other foreign objects pose significant concerns to consumer health. Consequently, more sophisticated devices capable of identifying these hard-to-detect contaminants in food are needed; hence, the food X-ray inspection machine!

This article explores how X-ray inspection systems transform meat safety, from detecting the smallest bone fragments to utilizing cutting-edge dual energy technology.

The Necessary Role of X-Ray Inspection in Meat Processing

X-ray inspection machines are designed to identify various contaminants in meat products, including bones, metal fragments, and other foreign objects. The density variations between meat and contaminants like bones or metal objects create clear contrasts in the X-ray images, making identifying and isolating unsafe products easier.

These systems utilize Dual-energy X-ray inspection systems to produce detailed pictures of the internal structure of meat, highlighting any anomalies and impurities. This technology can detect hard and soft contaminants that other inspection methods, such as metal detectors, may fail to identify. Therefore, the device ensures that only safe, contaminant-free meat reaches consumers.

How X-Ray Inspection Machines Detect Contaminants in Meat

X-ray inspection machines are designed to identify various contaminants in meat products, including bones, metal fragments, and other foreign objects. The density variations between meat and contaminants like bones or metal objects create clear contrasts in the X-ray images, making identifying and isolating unsafe products easier.

These systems utilize dual-energy X-rays to produce detailed pictures of the internal structure of meat, highlighting any anomalies and impurities. This technology can detect hard and soft contaminants that other inspection methods, such as metal detectors, may fail to identify. Therefore, the device ensures that only safe, contaminant-free meat reaches consumers.

Detecting Small, Calcified, and Hard Bones: A New Standard in Safety

One of the most significant challenges in meat processing is the detection of small, calcified, or hard bones. In fact, metal detectors and other traditional methods, like manual inspection, standard x-ray machines often overlook these bones, which may pose health hazards to consumers. However, Dual Energy X-ray inspection systems provide a solution by identifying bones of all sizes, even those embedded deep within the meat.

The precision offered by these systems sets a new standard in meat safety, ensuring that all contaminants, regardless of size or composition, are identified and eliminated. With Dual Energy X-ray inspection, even bones as small as 1mm in size are detectable. This high precision ensures that processors meet stricter food safety standards while delivering products free of potentially harmful contaminants.

Advancements with Dual Energy X-Ray Inspection for Bones

The evolution of X-ray technology has reached new heights with the introduction of dual-energy X-ray inspection systems. These advanced systems outperform traditional single-energy systems, particularly when detecting bones in meat products. Dual-energy X-ray inspection uses two different energy levels to capture more detailed information about the internal composition of meat.

What is Dual Energy X-Ray Inspection for Bones?

Dual energy X-ray inspection is an advanced technique that uses two different X-ray energy levels to analyze the density and composition of materials within meat products. By capturing images at two energy levels, the system can generate more accurate and detailed contrasts between meat and bones. This method is particularly effective for detecting small, calcified bones and other potential contaminants often missed by traditional X-ray systems. Dual energy X-ray inspection enhances the detection of contaminants by providing clearer, more defined images, making it ideal for ensuring the highest level of safety in meat processing.

Why Dual Energy Technology Enhances Meat Safety?

The introduction of dual-energy X-ray technology represents a significant leap in food safety, particularly for the meat processing industry. Its ability to identify even the smallest contaminants, especially tiny bones that are often hardest to detect, offers a precision level unmatched by traditional X-ray systems.

Consequently, this technology reduces the risk of contaminated meat reaching consumers, thus helping processors avoid costly recalls and potential health hazards. A typical example of this device is the Foodman’s dual Energy X-ray inspection. The device is sophisticated and equipped to detect the tiniest bones in meat products. It leverages FDX technology, a breakthrough in precision detection.

FDX technology helps improve the accuracy of bone identification by analyzing the subtle differences in density between meat and bone, ensuring that even the most challenging contaminants aren’t missed. In addition, the Foodman’s X-ray system is equipped with AI, thanks to the FOODMAN Intelligent Algorithm Platform (FIAP).

This AI-driven technology ensures the device continuously learns and adapts to the inspection environment. The intelligent platform’s smart learning feature helps enhance the system’s ability to detect food contaminants quickly and precisely, optimizing safety and efficiency in meat processing.

Comparing X-ray Systems to Traditional Inspection Methods

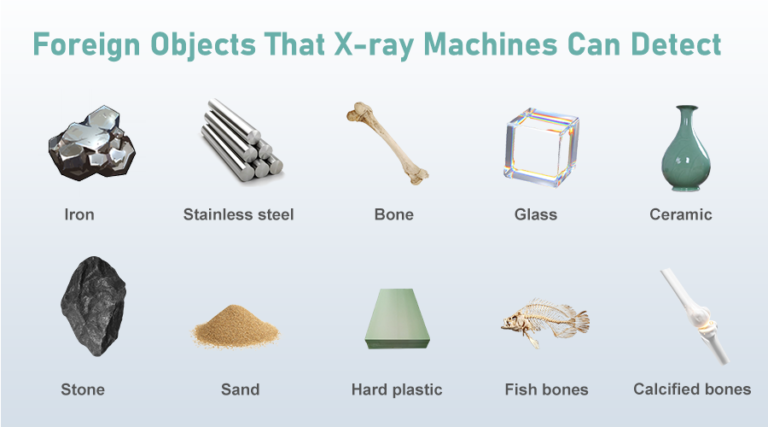

Traditional inspection methods, primarily manual checks and metal detectors, have long been used in meat processing to identify contaminants and promote consumer safety. However, even metal detectors are limited to detecting metal foreign objects; they struggle with other non-metallic contaminants, like bones, stone, plastic, glass, etc.

Here’s where the X-ray inspection system showcases its superiority, offering a more advanced and reliable solution. Through its cutting-edge technology, X-ray systems can detect a wider range of food contaminants with better accuracy and efficiency, making them a superior choice for modern meat processors.

Limitations of Traditional Inspection Methods in Meat Processing

The main limitation of traditional inspection methods, such as visual inspections or manual handling, is the high potential for human error. While they may be effective for detecting general contaminants, they are unreliable for detecting small or hidden contaminants within meat products.

For example, metal detectors, which used to be a mainstay in the industry, are limited to identifying metallic objects. They cannot detect non-metallic contaminants such as bones, plastic, or glass. In addition, the performance of metal detectors may be compromised by product packaging or variations in the product’s moisture content. As a result, these methods often fail to meet the stringent safety standards required in today’s food industry, as they leave room for potential contamination.

How X-Ray Inspection Systems Outperform Metal Detectors

As hinted above, X-ray inspection systems are more versatile than metal detectors, offering superior detection capabilities across various contaminants. Unlike metal detectors, which can only identify metallic foreign objects, X-ray systems can detect metallic and non-metallic contaminants, including bones, plastic, shells, stones, and glass. They are also capable of scanning through a variety of packaging materials without compromising accuracy.

Moreover, X-ray systems, such as those developed by Foodman, are equipped with advanced imaging technology and intelligent algorithms. This tech enables them to detect even the smallest bones and other hazards accurately. This ensures that meat products are thoroughly inspected for potential contaminants, providing safety and quality control that traditional methods simply cannot match.

Consumer Safety: Why Advanced Technology Matters

Consumer safety is paramount to the food industry, which is why improved methods of preventing the release of contaminated food products into the market are needed. Moreover, there seems to be a rise in concerns about foodborne illnesses and contamination. Therefore, food manufacturers and meat processors must adopt advanced technologies that better protect consumers.

X-ray inspection systems have emerged as the gold standard in detecting contaminants and ensuring product safety. As we have emphasized, the device is more reliable and offers better detection capabilities than traditional inspection methods.

Therefore, all food manufacturers and meat processors must invest in these advanced systems. Besides protecting their customers, these companies build trust and loyalty by delivering high-quality, safe products.

How X-Ray Inspection Protects Consumers From Contaminants

X-ray inspection systems are designed to safeguard consumers by identifying contaminants that could pose serious health risks. They detect metallic and non-metallic foreign objects, including bones, plastic, glass, and other materials that may be introduced during processing. By catching these contaminants before the product reaches consumers, X-ray inspection systems significantly reduce the risk of foodborne illnesses and injuries. Furthermore, with real-time detection capabilities, these systems ensure that any compromised products are removed from the production line immediately, enhancing the overall safety of meat products.

Revolutionizing Meat Safety with X-Ray Inspection Technology

X-ray inspection technology is transforming how meat processors handle safety and quality control. Through the use of advanced imaging, dual energy X-ray technology, and intelligent algorithms, companies like Foodman are setting new standards for meat safety. Besides improving the detection of bones and contaminants, this technology also streamlines the inspection process, increasing efficiency and reducing waste. The result is a safer, more reliable meat processing system that protects consumers while maintaining high productivity and profitability for processors. As X-ray technology continues to evolve, it will remain a crucial tool in revolutionizing meat safety.

Conclusion

Since their invention, X-ray inspection systems have been a revolutionary technology in the food industry. They offer unparalleled precision in detecting contaminants such as bones, plastic, and metal, promoting meat and food safety. Advanced technologies like dual-energy X-ray systems and intelligent algorithms ensure the highest level of protection by identifying even the smallest and hardest-to-detect contaminants.

As traditional methods struggle to keep up with modern safety standards, X-ray systems are the most reliable solution for ensuring consumer protection. Therefore, all food manufacturers and meat processors should consider adopting these technologies to enhance product quality and consumer trust, setting a new standard for safety in the food industry.