Introduction

X-ray inspection systems are critical in food safety, helping manufacturers detect contaminants and ensure product quality. These systems use non-invasive technology to identify foreign objects like metal, bone, and glass in food products, preventing them from reaching consumers.

With evolving standards in the food industry, the shortcomings of standard X-ray systems are becoming more pronounced. This is where the Dual Energy X-ray Inspection System comes into play, offering enhanced accuracy and precision.

This article explores the differences between dual energy and standard X-ray systems and why upgrading to dual energy will enhance food safety.

What is an X-ray Inspection System?

An X-ray inspection system detects contaminants and impurities in your products. It uses non-destructive technology to examine the internal structure of objects without harming the product. This device is used in various industries, particularly food production. Manufacturers use X-ray inspection systems to detect physical contaminants like metal, glass, bone, and other foreign materials that may compromise product quality or consumer safety.

The device transmits X-rays through a product, which are then absorbed or passed through based on the material’s density and composition. The resulting image allows operators to identify any discrepancies or contaminants. Therefore, X-ray inspection systems help ensure effective compliance with food safety standards and enhance overall product quality.

Overview of X-ray Machines in Food Safety

As mentioned, food X-ray machines are vital in ensuring food safety by helping manufacturers maintain product integrity and comply with stringent industry regulations. These devices enable the detection of foreign contaminants such as metal shards, bones, plastic, and even glass that may inadvertently enter the food during production.

The ability of X-ray systems to detect such contaminants, even when embedded in food products, makes them valuable for maintaining high hygiene and safety standards. In addition, they may also prove effective in ensuring products maintain consistent fill levels and accuracy in products released into the market. They help manufacturers meet strict regulatory demands and build customer’s trust in a brand.

Introduction to Standard X-ray Inspection Systems

Standard X-ray systems transmit a single energy spectrum of X-rays through the inspecting product. The denser the material, the more X-rays are absorbed, creating a contrast in the resulting image. Operators can then review the pictures to identify foreign materials or inconsistencies.

Standard X-ray inspection systems are adequate for detecting materials with significantly different densities from the food or product you are inspecting. They are widely used in various food industry sectors for detecting contaminants like metal, glass, and dense foreign objects. They are particularly effective in monitoring packaged foods, bulk items, and liquids.

However, a significant limitation of standard X-ray systems is their reduced ability to detect low-density materials, such as small bones, soft plastics, or rubber. Consequently, this system may become ineffective when inspecting products like poultry and fish with small bones. Standard X-ray inspection systems may fail to identify the minimal contrast between the bone and the surrounding tissue.

Understanding Dual Energy X-ray Inspection Systems

Dual energy X-ray inspection systems represent a significant advancement in food inspection and safety technology. They offer superior detection capabilities by analyzing products at two different energy levels. Unlike standard X-ray systems, which use a single energy spectrum, dual energy systems measure how different materials absorb X-rays at high and low energy levels.

This dual-spectrum approach allows for more precise differentiation between materials, especially those with minimal variations in their densities. Therefore, it is more effective for detecting contaminants and impurities that are challenging to detect using standard X-ray detection systems.

Food manufacturers use dual energy X-ray systems to detect a wider range of contaminants, including calcified bones, stones, sands, shells, and cartilage. This ability makes them a more valuable detection device for inspecting complex products like poultry, fish, and ready-to-eat meals.

How Does a Dual-Energy X-ray Inspection System Work?

Dual Energy food X-ray machine operates on a simple yet sophisticated principle. Like the standard X-ray inspection systems, they emit X-rays but release them at two different energy levels (high and low). The dual energy system’s ability to distinguish between materials is based on differences in energy absorption. It compares the absorption patterns between the two energy levels, enabling accurate identification of the different materials inspected.

Denser objects, like bones or metals, absorb more energy from the higher-energy X-rays, while less dense materials, such as food tissue, absorb less. For example, in poultry processing, the bones and meat have different absorption rates, even if they are close in density. This enables the system to detect small, low-density bones that standard systems might miss.

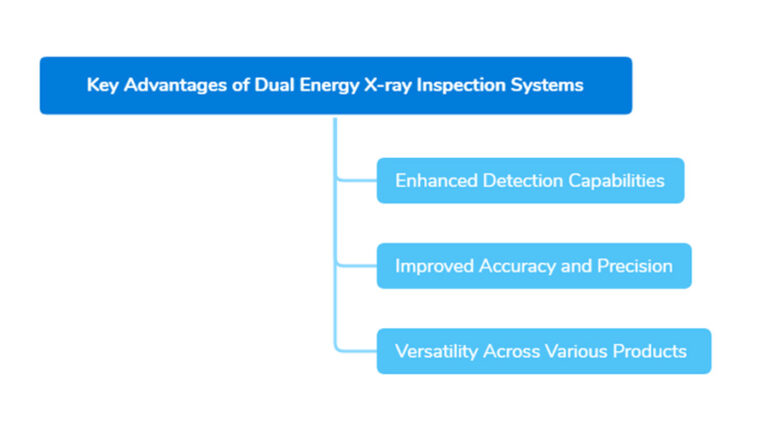

Key Advantages of Dual Energy X-ray Inspection Systems

We have already hinted at some advantages of dual-energy food X-ray inspection systems. This section will emphasize the critical ones.

Enhanced Detection Capabilities

One of the most significant advantages of dual energy X-ray systems is their superior detection capabilities. Compared to other detection systems, they can distinguish small bones, including calcified and hard bones, from the actual product. With advanced technologies like FDX (FOODMAN Dual Energy X-ray), the detection capabilities are elevated to a new level.

For example, this device features FIAP—FOODMAN Intelligent Algorithm Platform—which allows it to detect the most challenging contaminants. Its advanced algorithms allow it to identify irregularities in shape, weight, and density in food products. This enables it to separate food material from impurities like bone, glass, shells, stones, and metal, ensuring the release of only products of the highest standards to consumers.

Improved Accuracy and Precision

Dual energy X-ray systems offer improved accuracy by minimizing false positives, a common issue in standard X-ray systems. This enhanced precision is achieved through the system’s ability to differentiate between different materials more effectively. For example, when soft plastics or small bones might be mistaken for food tissue, the dual energy system’s advanced detection capabilities ensure that only genuine contaminants are flagged.

Versatility Across Various Products

Another feature of dual energy X-ray systems that makes them highly beneficial to the food industry is their versatility. The device is suitable for inspecting various products with varying densities. Whether it is bulk items or individually packaged foods, the system can effectively scan products with different compositions, making them suitable for diverse applications in the food industry. The dual energy X-ray technology provides a reliable solution across multiple food categories. It is ideal for detecting foreign objects in identifying small bones in dense protein products like fish or poultry.

Comparing Dual Energy and Standard X-ray Inspection Systems

The dual energy X-ray inspection system is a relatively new technology, offering superior capabilities when detecting contaminants in a product. Indeed, the standard X-ray inspection has been a reliable technology for detecting denser pollutants like metals and glass. However, it does not identify low-density materials like small bones or plastics.

In contrast, dual-energy X-ray systems offer a more advanced approach to overcome these limitations. Utilizing two energy levels to differentiate between materials allows them to offer more precise detecting solutions. This difference makes the dual-energy X-ray system far superior when detecting a broader range of contaminants, particularly in products like poultry and fish.

Detection Capabilities: Dual Energy vs. Standard X-ray

The standard X-ray system is best suited for detecting dense foreign objects like metal, glass, and stone. In contrast, the dual energy X-ray system can detect these foreign high-density objects, even the smaller ones that the standard systems fail to detect.

While standard X-ray systems typically excel when screening bulk or uniformly dense products, the dual energy system measures energy absorption at two levels, allowing it to differentiate between contaminants and food tissue more effectively.

Another feature distinguishing the dual energy system from standard X-ray technology is its ability to reduce false positives. Since the standard X-ray detection system considers lower-density materials like small bones and shells as part of food products like poultry and fish, it passes them as safe.

Applications of Dual Energy X-ray Inspection Systems

This section will discuss the applications of dual energy X-ray inspection systems in the food manufacturing and processing industry.

Detecting Small Bones in Poultry and Fish

These systems detect even the smallest bones, up to 1mm in diameter, essential for meeting stringent safety regulations and consumer expectations. A typical example is the FOODMAN Dual Energy X-ray, which offers up to 0.1mm resolution, ensuring the highest safety and quality in food inspection. They can detect calcified and hard bones in poultry and fish, providing a safer end product. This capability is crucial for manufacturers processing products like chicken or fish filets, where even a tiny bone can pose a severe safety risk to consumers.

Beyond Bone Detection: Versatile Applications

While detecting bones is a significant advantage, dual energy X-ray systems are versatile enough to detect various contaminants in food products. This advanced technology ensures the detection of materials that often go unnoticed by standard X-ray systems, including:

- Cartilage: Due to its low density, cartilage, especially in poultry and fish, can be difficult to detect using standard X-ray systems. However, this device can distinguish between cartilage and the surrounding tissue, ensuring that even non-calcified elements are identified and removed from the product line.

- Shells: In seafood processing, small shell fragments may be difficult to spot, posing a consumer risk. Dual energy X-ray systems are effective at detecting even the most minor shell pieces, removing them from products like shellfish or seafood-based items before they reach the market.

This device also effectively screens sand, stones, plastics, rubber, glass, and ceramics. It may be almost impossible to rid a product of these items, as some may even be a component of the packaging, but when mixed with the product, they become impurities. Still, the dual energy X-ray food inspection system can detect them, guaranteeing quality and safety.

Why Choose a Dual Energy X-ray Inspection System?

Dual energy X-ray inspection systems are an essential upgrade for food manufacturers seeking to meet higher safety standards and improve detection accuracy. Below, we examine why you should choose a dual energy X-ray inspection equipment over other detection machines.

Improving the Detection of Small Bones in Poultry Products

This article emphasizes the device’s ability to detect small bones in poultry products. In an industry where even the smallest bone can pose a health hazard, the precision of dual energy systems ensures that contaminants like calcified and hard bones are detected and removed from the production line.

While standard X-ray systems often struggle to identify such minute objects due to the similarity in density between bones and meat, the dual energy technology eliminates this challenge. This means higher product safety and reduced consumer complaints and product recall risk.

Staying Competitive in the Market

In today’s competitive food industry, staying compliant with stringent regulations while meeting consumer expectations is crucial. The dual energy X-ray systems help manufacturers meet these demands by offering more accurate, reliable inspection capabilities.

Consumers expect safe, high-quality products, and industry regulations are constantly evolving to meet these standards. By utilizing dual energy detection systems, manufacturers can ensure their products comply with food safety regulations, like those enforced by the FDA or European Union standards, while safeguarding their brand reputation.

Investing in the Future of Food Inspection

Adopting the latest X-ray inspection technology, such as dual energy systems, is an investment in the future of food safety. While the initial cost may be higher compared to standard systems, the long-term benefits make the device a more cost-effective choice. The enhanced detection capabilities mean reduced product recalls, less waste, and a smoother production process.

Moreover, the dual energy systems are designed to handle an extensive range of products, making them adaptable to changes in production lines or evolving safety standards. Also, equipping yourself with the latest technology gives you an edge as food safety regulations tighten.

Conclusion

The dual energy technology is new compared to the standard X-ray inspection system and has proven effective in revolutionizing the food industry. Its main selling point is its ability to accurately detect smaller contaminants and impurities that normally pass as food items using other X-ray inspection systems.

However, this ability is vital in promoting food safety and reducing the spread of contaminated food items to consumers. Therefore, it is paramount that all food manufacturers have this technology, such as the FOODMAN Dual Energy X-ray inspection system. This device will prove vital in ensuring long-term success in the food industry as demands for food safety continue to grow.