Introduction

Optical sorting machines have become essential tools in modern industries, enhancing accuracy, efficiency, and quality control. These advanced devices use cutting-edge technology to sort materials based on visual and physical characteristics, making them ideal for various applications.

The device offers vast applications across industries. Optical sorters are already reshaping how businesses operate, from ensuring food safety in processing facilities to improving recycling operations and manufacturing precision.

This article explores the fundamentals of optical sorting machines, their components, benefits, applications, and how to choose the right one for your business needs.

What is an Optical Sorting Machine?

An optical sorting machine is an advanced automated system designed to sort materials based on visual and physical characteristics. This device features high-speed cameras, sensors, and algorithms that enable it to identify and separate items by analyzing attributes like color, shape, size, and surface defects with remarkable precision.

Automated optical sorters are critical in ensuring product quality and consistency in food processing, agriculture, recycling, and manufacturing industries. For example, the Foodman vision inspection system represents a cutting-edge approach to optical sorting. It utilizes industrial cameras and AI algorithms to guarantee accurate product sealing and coding inspections, detecting and removing potential defects.

Vision sorting machines seamlessly integrate into existing production lines and provide practical solutions for industries such as pharmaceuticals, cosmetics, food, and beverages. The device enables these industries to continue maintaining quality and compliance with required standards.

Key Components of an Optical Sorter Machine

An optical sorter machine is an advanced technology assembly that delivers accurate sorting and inspection. The following components form the backbone of its functionality:

High-Resolution Cameras and Sensors

The most significant features of any optical sorter machine are the high-resolution cameras and advanced sensors. These devices capture detailed images and data from the materials passing through the machine. The cameras detect minute variations in color, texture, shape, and size, providing a visual foundation for precise sorting. In addition, the sensors enhance this process by measuring physical properties, ensuring the identification of even the smallest defects or inconsistencies.

AI and Machine Learning

Modern optical sorting machines rely on artificial intelligence (AI) and machine learning (FDM VISION) algorithms to process the data collected by cameras and sensors. These technologies enable the machine to learn and adapt to specific sorting criteria, improving accuracy. AI algorithms can recognize patterns, classify objects, and even predict defects based on historical data, ensuring 99.9% defect detection rates in systems like the Foodman vision inspection system.

Rejection Systems

Once the machine identifies unwanted or defective items, the rejection system takes over. This component uses mechanisms like mechanical diverters or automated arms to remove unsatisfactory products from the production line. Optical sorting systems operate at incredible speeds to maintain the flow of materials and ensure that only high-quality products continue.

How Do Optical Sorting Machines Work?

Automatic optical sorting machines seamlessly integrate advanced technology, ensuring efficiency and precision in sorting. This section will explore how optical sorting machines work.

The Process of Optical Sorting

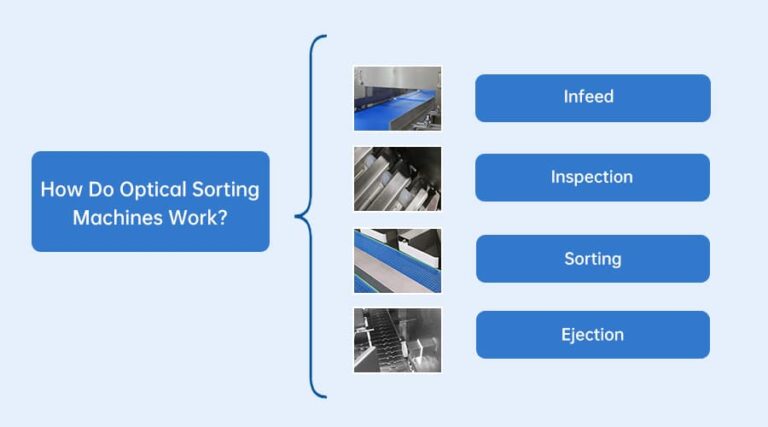

The process involves four key stages that work in sequence to identify, classify, and separate materials based on specific characteristics.

Infeed: How Products Are Fed into the System

The sorting process begins at the infeed stage, where products are systematically introduced into the machine. This is typically done using conveyor belts, vibratory feeders, or chutes, ensuring a steady and consistent flow. However, proper alignment is crucial to avoid overlapping or clogging, which might impact inspection accuracy.

Inspection: High-Speed Cameras Analyze the Materials

Once the materials are in place, the inspection stage commences. It involves high-speed cameras and sensors capturing detailed images and data. Advanced cameras observe various characteristics such as color, size, shape, and surface texture. The cameras operate in conjunction with sensors, enabling the identification of minute defects, such as discoloration, cracks, or deformities. All these actions are performed at remarkable speeds to prevent downtime.

Sorting: Algorithms Classify Materials Based on Predefined Criteria

After collecting data, the machine’s AI algorithms process and classify the materials. These algorithms are pre-programmed with sorting criteria, such as acceptable size ranges or specific color thresholds. The system uses the pre-set criteria to separate the materials into different categories, ensuring only items that meet quality standards continue on the production line.

Ejection: Reject Unqualified Products or Issue an Alarm

The final stage is ejection, where unqualified products are removed from the stream. Depending on the machine’s design, this is done through mechanisms like mechanical arms or flaps. If a significant issue arises, the system may alarm or pause operations to prevent further quality compromises.

Benefits of Using Optical Sorting Machines

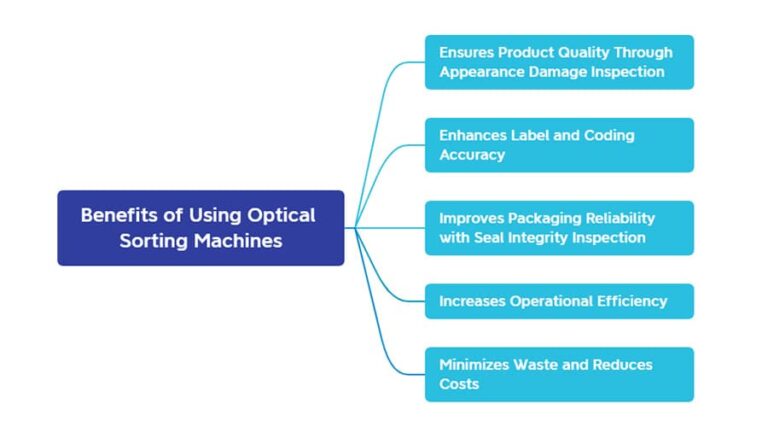

Optical sorting machines offer numerous advantages that streamline production processes, improve product quality, and enhance operational efficiency. Below are some of the main benefits of this device.

Ensures Product Quality Through Appearance Damage Inspection

One of the most significant benefits of optical sorting machines is their ability to detect appearance-related defects. These systems can identify scratches, dents, cracks, and other surface damage on materials like aluminum cans, blister packs, and plastic containers. This function ensures that only visually flawless products reach the market, safeguarding brand reputation and consumer trust.

Enhances Label and Coding Accuracy

Modern optical sorting machines feature label and coding inspection capabilities, which help ensure packaging compliance. They can detect incorrect or missing labels and verify the presence and quality of inkjet codes, barcodes, and 1D/2D codes. By eliminating labeling errors, businesses reduce the risk of regulatory penalties and improve customer satisfaction.

Improves Packaging Reliability with Seal Integrity Inspection

Optical sorting systems are vital in inspecting seal integrity for bottles, cans, and bags. They identify potential issues such as leakage, contamination risks, misaligned seals, and improper flatness, ensuring that products remain secure throughout their shelf life. This feature minimizes waste and prevents customer complaints related to packaging failures.

Increases Operational Efficiency

Automatic optical sorting systems operate at high speeds, allowing manufacturers to inspect and sort large volumes of products in significantly less time than manual processes. This efficiency reduces production bottlenecks, improves throughput, and ensures consistent quality, even during peak demand.

Minimizes Waste and Reduces Costs

By accurately identifying defective items and separating them early in the production line, optical sorting machines help minimize waste. They prevent faulty products from undergoing further processing, which saves time and resources. In addition, their ability to perform real-time inspections reduces the likelihood of costly recalls or product returns.

Common Applications of Optical Sorting Machines

These sophisticated devices offer vast applications across various industries. This section will explore sectors that rely on optical sorting machines for quality control and maintaining industry standards.

Food Processing and Quality Control

Optical sorting machines are critical in food processing because they ensure quality and packaging integrity. These systems confirm the alignment and readability of product labels, including vital information like nutrition facts and branding.

They also inspect seals on packaging, such as canned goods and sauces, to prevent leakage and contamination. In addition, the optical food sorter machine helps identify scratches, dents, and gaps in cans and seals to guarantee product freshness and readiness for distribution.

In the pharmaceutical sector, optical sorting machines ensure compliance and safety. Pharmacists use them to inspect blister packs for tears and misalignments, safeguarding the quality of medications. These machines also aid in validating barcodes for batch tracing and ensuring regulatory compliance.

Optical sorting systems assess the seal quality of sachets, tubes, and containers to maintain product sterility and prevent contamination. By automating these critical inspections, manufacturers can reduce errors, ensure patient safety, and streamline production processes.

Cosmetics & Personal Care Industry

The cosmetic industry also uses optical sorting machine technologies to ensure high packaging standards. They inspect lotion, cream, and shampoo containers for flaws like deformations and scratches. These devices also help confirm that pouches and tubes are free from leaks or signs of tampering.

In the beverage industry, optical sorting machines optimize production by inspecting aluminum cans for micro-cracks, gaps, and dents that could lead to filling or distribution issues. They verify promo codes and batch information, ensuring accurate placement and readability for marketing and traceability purposes.

In addition, the machines perform surface inspections to detect scratches or damage, maintaining the visual appeal of cans on store shelves. These capabilities enable beverage manufacturers to minimize defects, reduce waste, and deliver a polished product.

The optical sorting machine also benefits the seafood industry, ensuring high-speed processing and precision. It sorts seafood based on size, color, and quality, ensuring that only premium products are packaged and distributed. Its ability to handle a wide variety of seafood, from shrimp to fish fillets, enhances processing efficiency and ensures consistency in the final product.

A typical optical sorting machine streamlines the sorting and grading of fruits and vegetables. They classify produce based on color, size, and ripeness, ensuring uniformity in quality. By identifying blemishes, bruises, or foreign objects, the machines ensure that only fresh, high-quality produce reaches consumers.

How to Choose the Right Optical Sorting Machine for Your Business

While optical sorting machines offer vast applications to various industries, selecting the right device is critical. This section assists you in making the right choice.

Factors to Consider

When selecting an optical sorting machine, assessing the technology powering the device is crucial. Manufacturers must ensure to choose devices equipped with the following:

- Advanced machines integrated with AI and machine learning algorithms to precisely detect even the most minor defects.

- High-speed data processing capabilities to enable real-time inspections, ensuring seamless operation even in high-volume production lines.

In addition, consider the machine’s compatibility with your product range—whether it can handle diverse materials like food, pharmaceuticals, or industrial goods.

Energy efficiency and scalability are also important. Ensure that the machine you select will remain valuable, even as your business grows, while keeping operational costs low. Evaluate these features carefully to make an informed decision.

After-sales Service and Support

Reliable after-sales service is essential when investing in an optical sorting machine. For example, optical sorting machine manufacturers like Foodman stand out by offering comprehensive support to their customers. From installation and calibration to operator training, we ensure your machine is optimized for top-notch performance.

Conclusion

Optical sorting machines are transformative technologies that drive efficiency and quality across diverse industries. By leveraging advanced features like high-resolution cameras, AI algorithms, and customizable configurations, they meet the unique needs of food processing, pharmaceuticals, and recycling sectors.

Choosing the right machine involves evaluating technology, scalability, and after-sales support. Partnering with a trusted manufacturer like Foodman ensures you receive top-tier products and reliable service. As businesses prioritize precision and sustainability, optical sorting machines remain essential for achieving operational excellence.