Introduction

Precision and efficiency are vital in modern manufacturing and processing. Because of their unique functionalities, weight sorting machines, often called weight graders, are essential tools across various industries. These automated systems are designed to categorize and group products based on weight. They are integral to industries where uniformity and precise weight measurements are critical.

Weight sorting machines ensure that products meet strict quality standards, enhance operational efficiency, and help maintain regulatory compliance. They offer these functions to food manufacturing industries, chemical plants, pharmaceutical companies, etc.

This article provides insights into the intricacies of weight sorting machines, exploring their functions, types, and the significant benefits they bring to different sectors.

What Is Weight Sorting?

Weight sorting is the process of grading and sorting products based on their weight. This technique ensures that items meet specific weight criteria, which is crucial for maintaining consistency and quality. It is particularly common in the food processing, manufacturing, and packaging industries. It helps to streamline production and improve efficiency.

The Role of Weight Sorting in Modern Industries

Weight sorting is an important process in companies that deal in food production and processing. It helps ensure weight uniformity, product consistency, and conferring quality. Most food production companies use weight sorting techniques in grading fruits, vegetables, poultry, and seafood, ensuring each piece meets the required standards.

General manufacturing companies may also utilize weight sorting to ensure each part and component they create meets precise weight specifications. This application may effectively reduce waste and improve overall product reliability in the market. Therefore, weight sorting helps to enhance efficiency, boosts productivity, and ensures compliance with industry regulations.

How do Weight Sorting Machines Work?

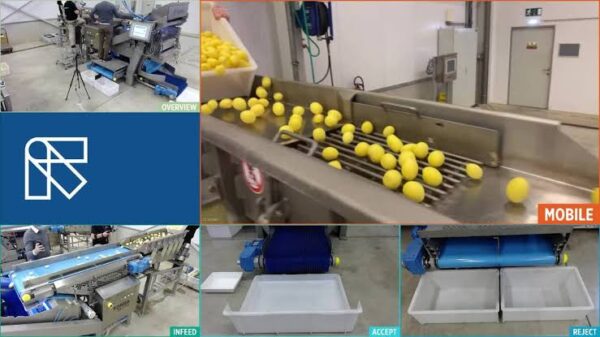

Weight sorting machines are automated, recording the weight of each item that passes along its conveyor belt. These machines have built-in sensors that enable them to measure the weight of each item, which then permits the categorization of these items based on predefined weight ranges.

Depending on the type of machine, items may be sorted into different bins or redirected to various processing lines. In addition, advanced weight graders may integrate visual inspection systems to enhance accuracy. Such machines ensure that only items that meet specific weight and quality criteria proceed further in production.

What are Weight Sorting Machines Used For?

The weight sorter machines perform the weight sorting process, which involves categorizing products based on weight. We already informed you that a product’s weight may prove important in ensuring uniformity and adherence to quality standards.

Though the operations of this device are pretty straightforward, they are vital in industries—particularly in food processing. These devices also benefit the pharmaceutical sector, where weight uniformity is integral. Deviation from preset weight standards in pharmaceuticals may harm patients using such medications. Consequently, this industry also requires this device.

That said, the weight sorting machine helps to confer product consistency and reduce overfilling and waste of raw materials.

Types of Weight Sorting Machines

Manufacturing companies make use of various weight sorting machines. Below, we explore the common weight grader devices.

- Single/Dual Lane Weight Grader: Single and dual lane weight graders are designed to handle high volumes of products efficiently. As their name indicates, these machineshttps://www.easyweigh-group.com/products/single-lane-weight-grader/ feature one or two lanes on their conveyor belt, through which items pass and are weighed individually. They are ideal for processing lines requiring precise weight categorization and can simultaneously sort products into multiple weight categories. The standard application of this device includes sorting fruits, vegetables, and small packaged goods.

- Rotating Trays Weight Grader: Rotating trays weight graders use a series of rotating trays to weigh and sort products. As items move along the conveyor, they are placed onto rotating trays that measure their weight. The trays then rotate to direct the items into appropriate bins or processing lines based on weight. This weight sorting machine is primarily used for handling irregularly shaped or delicate items, such as seafood and certain fruits.

- Visual Inspection and Weight Grader: Visual inspection and weight graders integrate the functionalities of weight measurement with visual inspection technologies, such as cameras and sensors. This device ensures products meet both weight and quality standards. It can detect defects variations, including potential quality issues, while also sorting items by weight. This dual functionality makes it highly effective in industries where both weight and visual quality are critical, such as poultry and high-value produce.

Applications of Weight Sorting Machines

Weight sorter machines offer diverse applications across various industries. Below is a detailed look into their applications.

Grader weight machines are used in the poultry industry to grade and group chicken and other poultry products based on their weight to ensure consistency and quality. These machines help categorize whole birds, parts, and processed products for packaging and further processing. Recommend models of chicken sorting machines for poultry products include the following:

Rotating Trays Weight Grader

Seafood processing requires precise weight sorting to maintain quality and ensure compliance with market standards. Weight graders in this industry help sort fish, shellfish, prawns, lobsters, and other seafood based on weight, ensuring uniformity in packaging and processing. Typical weight sorting machines for grouping, sorting, and grading seafood include the following:

Visual Inspection and Weight Grader

Weight sorting machines are essential in the fruits and vegetables industry to ensure products meet specific weight criteria, enhancing uniformity and quality. These machines help sort a wide range of produce, from small fruits like tomatoes to larger melons.

Recommend models of vegetables and fruits sorting machines include the following:

Dual Lane Weight Grader

Benefits of Using Weight Sorting Machines

We have already hinted at some of the advantages of weight-sorting machines. However, his section will take a more comprehensive look into their benefits.

Efficiency and Productivity Gains

Weight sorting machines are automated devices operating, reducing the over-dependence on human labor. They allow manufacturing and processing companies to weigh various products just by moving over the machine instead of the manual method of weight inspection. Therefore, they significantly enhance efficiency and productivity by automating the sorting process.

These devices can handle large volumes of products at high speeds, hastening production’s processing and packaging phase. Since the weight sorting device is automated, it minimizes human error, ensuring more consistent and reliable results. The increased throughput allows companies to meet production targets more effectively, ultimately boosting overall productivity.

Quality Assurance and Compliance

Weight sorting machines help maintain high-quality standards by ensuring products meet specific weight criteria. This consistency is crucial for customer satisfaction, building trust, and enhancing brand reputation.

Moreover, these machines aid in complying with industry regulations and standards, which often mandate strict weight specifications for products. The precise sorting capabilities of weight graders ensure that only products meeting the required standards proceed to packaging and distribution, thus minimizing the risk of non-compliance and potential fines.

Data Management and Reporting

Sophisticated weight sorting machines feature advanced data management and reporting functionalities. These systems collect and analyze data on each product sorted, providing valuable insights into production trends, weight distribution, and potential areas for improvement.

This data may provide more insights into optimizing processes, reducing waste, and enhancing overall efficiency. In addition, the detailed reports obtained from these machines prove important in performance tracking, ensuring transparency, and facilitating more informed decision-making.

Conclusion

Weight sorting machines are beneficial tools that many manufacturing companies should possess. They are already a mainstay in food processing and manufacturing. Their ability to enhance efficiency, ensure quality compliance, and provide valuable data insights makes them vital to modern production lines. Therefore, by investing in weight sorting machines, companies can achieve significant operational improvements and maintain high quality and weight consistency standards.