Introduction

In the food processing industry, high efficiency and accuracy have driven the development of fruit sorting machines. These machines are crucial for ensuring fruit quality by grading them based on size, shape, color, and ripeness. With automated sorting technologies, fruits are processed quickly, reducing manual labor and boosting productivity. This blog will discuss how fruit sorting machines operate, highlighting key technologies such as optical sorting and automated vision systems.

What Is a Fruit Sorting Machine?

A fruit sorting machine is an automated system in food processing that classifies fruits by quality parameters like size, color, shape, and ripeness. These optical sorters are essential for maintaining high quality and reducing manual labor in fruit handling. They use advanced technologies, including optical and vision sorting systems with cameras, sensors and algorithms to assess the fruit on the production line.

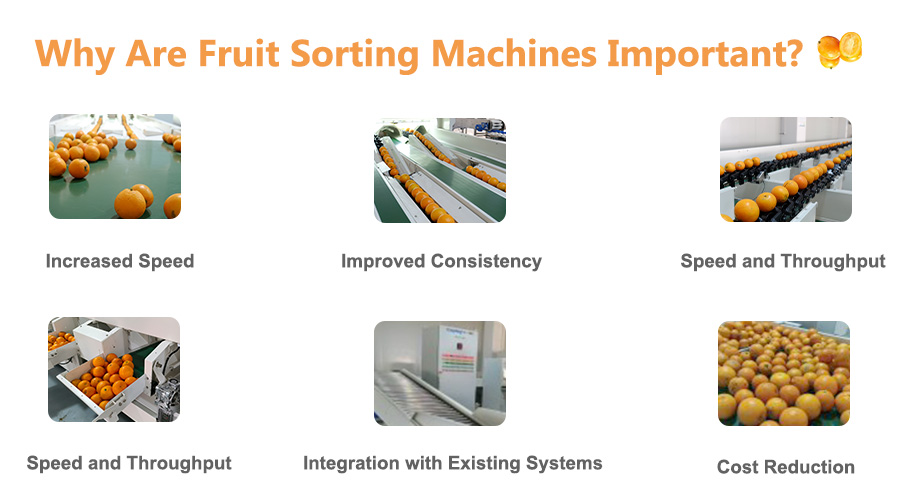

Why Are Fruit Sorting Machines Important?

Fruit optical sorting machines help maintain consistent product quality by sorting fruits that meet certain standards. This allows for efficient, high-speed processing of large batches, ensuring that only the best fruits make it to packaging or further processing. The advantages of using these fruit sorters include:

Increased Speed: They accelerate the sorting process compared to manual methods.

Improved Consistency: Uniform inspection leads to consistent quality.

Cost Reduction: Automation lowers labor costs and minimizes human error.

These sorting machines are essential in industries from fresh produce packaging to processed fruit production, where high quality is crucial.

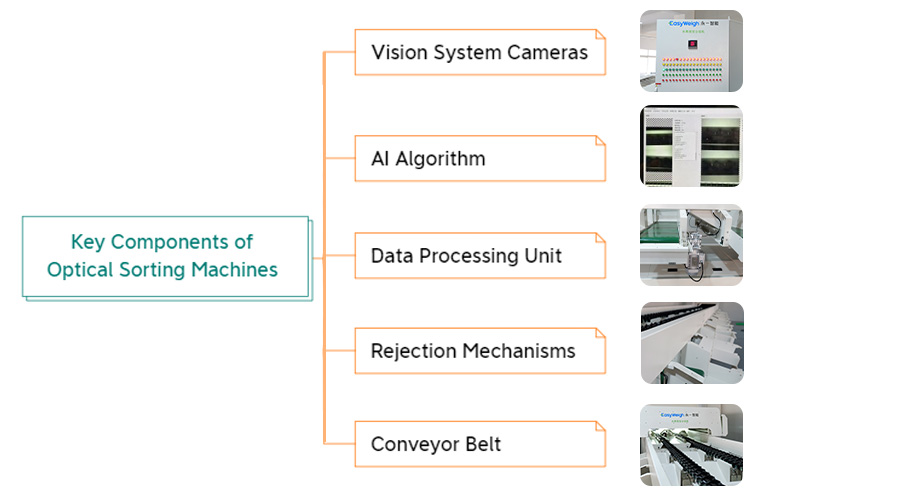

Core Components of an Optical Sorting Machine

Modern fruit sorting systems use advanced imaging technology to identify defects and classify fruits. These machines consist of key components that work together for efficient inspection and sorting.

Key Components of Optical Sorting Machines

Modern fruit sorting systems employ advanced imaging technology to identify defects and classify fruits accurately. These machines comprise key components designed for efficient inspection and sorting.

Vision System Cameras

Vision system cameras are essential in optical sorting machines. These multiple high-speed CCD industrial cameras and high-definition lenses capture images of fruits in real time as they pass through the machine. The cameras are often equipped with multiple lenses or imaging sensors that enable 360-degree inspection of the fruit’s surface.

AI Algorithm

Using Foodman’s self-developed AI algorithm, a sorting model can be quickly built, and data optimization can be completed within a week to enhance sorting accuracy.

Data Processing Unit

Once images are captured, they are processed by FIAP image processing. The system uses sophisticated algorithms to analyze the fruit’s features, such as size, shape, color, wrinkled, skin, broken skin, etc. to determine whether it meets the required quality standards.

Rejection Mechanisms

Fruits that fail to meet quality standards are ejected from the conveyor belt using mechanisms like air jets or vibratory feeders, depending on the sorting machine design.

Conveyor Belt

The conveyor belt transports fruits at a consistent speed, allowing them to pass under cameras and sensors for inspection and directing them to the appropriate sorting area.

How Does a Fruit Sorting Machine Work?

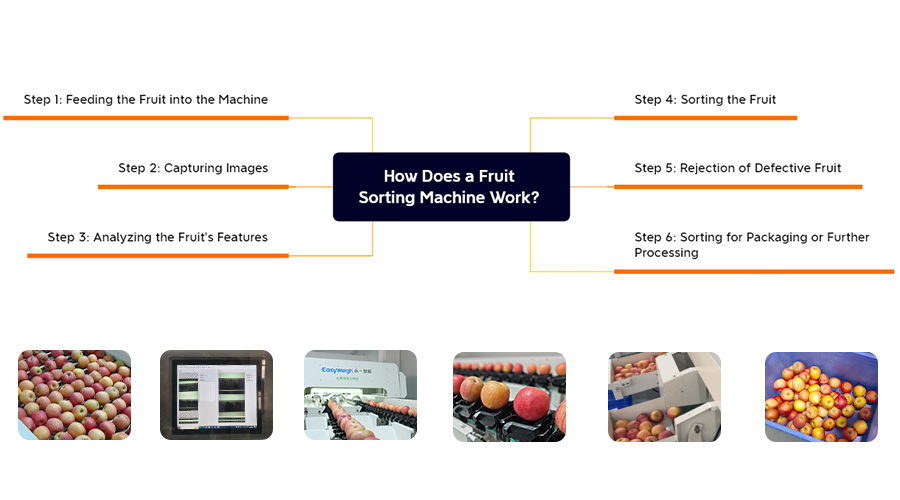

Now, let’s examine how a fruit sorting machine works in real time, from the moment the fruit enters the system to the point where it is sorted and categorized.

Step 1: Feeding the Fruit into the Machine

At the start of the sorting process, fruits are placed onto a conveyor belt. Depending on the setup, the fruits might be fed into the system manually or automatically. As they move along the conveyor, they are spaced out in a single file to ensure each fruit can be individually analyzed.

Step 2: Capturing Images

As the fruit moves along the conveyor belt, vision system cameras mounted above, below, or beside the conveyor capture high-resolution images. These cameras take snapshots of the fruit’s exterior from multiple angles to ensure thorough inspection. The lighting system ensures the fruit is illuminated evenly, enhancing the visibility of its color and surface features.

Step 3: Analyzing the Fruit’s Features

Once the images are captured, the FIAP image processing technology processes the data. It analyzes the color, size, shape, and surface condition of the fruit. For example, if the machine is sorting apples, it might assess the following features:

Color: Are the apples the correct shade of red or green? If not, they may be rejected.

Size and Shape: Is the fruit misshapen or too small or large for the market’s specifications? These fruits are sorted out accordingly.

Surface Condition: Are there any blemishes, bruising, or other defects that would affect the fruit’s marketability?

The vegetables sorting system uses algorithms that compare the captured images with pre-programmed standards or quality thresholds.

Step 4: Sorting the Fruit

Based on the analysis, the sorting machine classifies the fruit into different categories. The quality fruits pass through the system, continuing on the production line for packaging or further processing.

Step 5: Rejection of Defective Fruit

The fruit is ejected from the conveyor belt if it does not meet the required quality standards. This can be done in several ways:

Air Jets: High-speed air jets blow the defective fruit off the conveyor.

Vibratory Feeder Systems: These systems use vibrations to push defective fruit into waste hoppers.

The rejected fruit is discarded or redirected for secondary processes like juicing, canning, or composting.

The use of vision sorting machines in fruit processing lines has transformed the industry. Here are the key benefits:

Step 6: Sorting for Packaging or Further Processing

Once the fruit is inspected, it is categorized based on quality and directed to the appropriate packaging or further processing stage. For example, premium-quality fruits might be packaged for fresh market sales, while lower-quality fruits may be used for processed products.

Benefits of Vision Sorting Machines

The use of vision sorting machines in fruit processing lines has transformed the industry. Here are the key benefits:

a. Increased Efficiency

Vision sorting machines quickly process large batches of fruit, boosting throughput without compromising quality.

b. Enhanced Accuracy

Vision sorting machines detect minor defects, such as bruises and discolorations, ensuring that only the highest-quality fruits reach consumers and reducing waste.

c. Consistency and Standardization

Vision sorting machines operate based on algorithms and provide a uniform sorting process, eliminating variations seen with human workers.

d. Reduced Labor Costs

Automation cuts the need for manual labor, lowering costs and minimizing human error, which enhances productivity.

e. Better Handling of Delicate Fruits

Sorting machines are gentle on the fruit during the sorting process. Unlike manual sorting, where fruits may be damaged by rough handling, vision sorting machines use precise, non-contact methods like air jets and mechanical arms to remove defective fruits. This ensures the fruit remains in optimal condition.

f. Scalability

Producers can easily scale operations by adding machines or upgrading systems to meet increasing demand.

g. Improved Traceability

Vision sorting systems offer data logging features, allowing producers to monitor quality and ensure standards are met.

Conclusion

A fruit sorting machine is crucial in modern food processing. It utilizes vision and optical sorting technologies to assess fruit quality in real time. It classifies fruits by size, shape, color, and surface condition, ensuring only the best reach the market.

These optical sorting machines’ advantages—such as increased efficiency, improved accuracy, and lower labor costs—make them essential for fruit producers. Investing in a quality fruit sorting machine can streamline operations and enhance product quality.

FAQs

A fruit sorting machine is an automated system that inspects and categorizes fruits based on size, color, shape, and surface condition using vision sorting and optical sorting technology.

Optical sorting machines use vision system cameras to capture high-resolution images of the fruit. These images are then analyzed by FIAP image processing technology to detect defects, measure size, and assess color. The system then sorts the fruit accordingly.

Yes, many vision sorting machines use infrared lighting.