Introduction

The food industry is highly competitive and complex, especially when dealing with perishable goods like tomatoes. Consequently, tomato processing relies on efficiency and product quality for success. This case study highlights how Easyweigh’s advanced optical sorting machine revolutionizes operations in a tomato processing factory. We addressed key challenges such as variability in tomato quality, manual sorting inefficiencies, and high-speed production demands.

However, by integrating cutting-edge technology like AI algorithms, high-resolution cameras, and precision ejection systems, Easyweigh significantly improved sorting accuracy and consistency. The result? A remarkable 25% yield boost showcasing the tomato optical sorting machines’ transformative power in optimizing productivity and reducing waste.

The Challenge in Tomato Processing

Tomato processing presents unique challenges due to the natural variability of the fruit and the demanding pace of modern production lines. Therefore, maintaining consistent quality while maximizing yield is a constant struggle for processors. Factors such as differences in tomato size, shape, ripeness, and surface defects make manual sorting inefficient and error-prone.

Moreover, with the increasing demand for high-speed production, traditional sorting methods often fall short, leading to waste, quality inconsistencies, and higher operational costs. Below, we emphasize some of the challenges associated with tomato processing.

Variability in Tomato Quality

As mentioned, tomatoes differ significantly in size, shape, and ripeness, making consistent grading and sorting difficult. Each batch often contains a wide range of tomatoes—from under-ripe green ones to overripe soft fruits—posing challenges for processors aiming for uniform quality. This variability affects the aesthetic appeal and processing efficiency, as inconsistent ripeness can impact taste, texture, and shelf life.

In addition, surface defects such as cracks, blemishes, and discoloration add another layer of complexity. While these imperfections are not always easily noticed, especially in high-speed production lines, they make manual detection unreliable. Undetected defects may compromise product quality, leading to customer dissatisfaction, increased waste, and potential financial losses.

Manual Sorting Limitations

Indeed, manual sorting is traditional, but it comes with significant limitations. Human workers face difficulties maintaining consistent accuracy, especially with long shifts, leading to sorting errors and reduced efficiency. Fatigue, subjective judgment, and varying skill levels may also contribute to inconsistencies, resulting in defective tomatoes slipping through the process or mistakenly rejecting good ones.

Furthermore, manual sorting is labor-intensive and expensive. It requires hiring and training workers for sorting tasks, which increases operational expenses. The dependency on human labor makes the process vulnerable to workforce shortages. Moreover, manual sorting simply cannot keep up with the speed and precision required for optimal output in fast-paced production environments.

Meeting High-Speed Production Demands

While manual sorting cannot keep up with the fast-paced industry, modern optical sorting in tomato processing facilities operates at high speeds to meet these growing market demands. The need for rapid throughput often compromises sorting accuracy, leading to either quality control issues or increased product waste.

High-speed production demands help enhance the sorting process and promote consistent quality assurance. In comparison, manual systems cannot deliver both simultaneously, causing bottlenecks in the production line. This inefficiency often causes production delays, reduced output, and a failure to meet strict industry standards. Therefore, processors require advanced solutions that can handle large volumes efficiently without sacrificing quality to remain competitive.

The Solution – Advanced Optical Sorting Machine

Advanced optical sorting machines offer a transformative solution to overcoming the challenges of tomato processing. These machines combine cutting-edge imaging technology, AI-powered algorithms, and precision ejection systems to streamline sorting processes.

This tomato sorting technology has proven to be a game-changer, particularly in high-speed production environments where manual sorting falls short.

Deploying Optical Sorting Machines in Tomato Processing

Easyweigh’s automatic optical sorting machines seamlessly integrate into tomato processing lines. This automated device works harmoniously with existing equipment. The deployment process involved positioning the sorters at key points where tomatoes pass through conveyor belts after initial cleaning and pre-sorting.

As tomatoes move along the conveyor, they enter the optical sorting system, where high-resolution cameras capture real-time images of each fruit. The Foodman AI algorithm processes these images instantly, identifying defects, inconsistencies in ripeness, size variations, and surface damage.

Upon detecting any anomaly, the system triggers its ejection mechanisms to remove defective tomatoes without disrupting the continuous workflow. This integration optimized the tomato processing efficiency, reducing reliance on manual labor, improving throughput, and ensuring consistent quality across large batches.

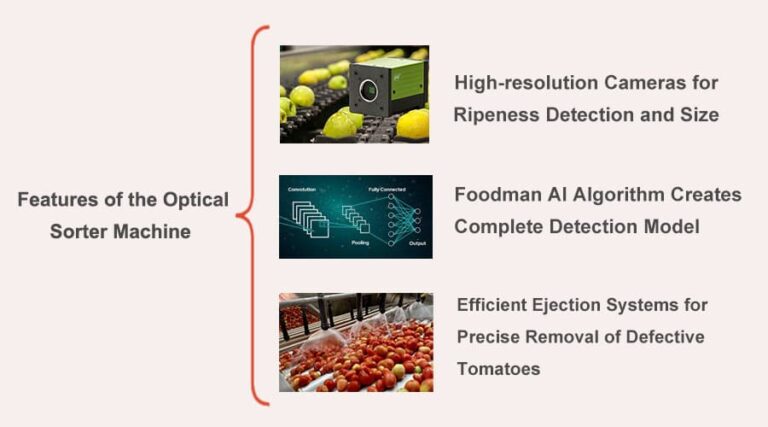

Features of the Optical Sorter Machine

Easyweigh’s optical sorting machines’ success in tomato processing relies on their advanced features designed to tackle sorting challenges with speed and precision.

High-resolution Cameras for Ripeness Detection and Size

As a typical vision sorting machine, it is equipped with high-resolution industrial cameras to detect subtle differences in tomato ripeness and size with remarkable accuracy. It operates as an optical color detector, using its camera to capture detailed images of each tomato as it passes through the system. The cameras analyze size, shape, and color gradients to determine ripeness levels—from green, partially ripe, to fully ripe. The ability to sort and grade tomatoes using cameras eliminates human error, enhances consistency, and significantly improves yield.

Foodman AI Algorithm Creates Complete Detection Model

The Foodman AI algorithm is perhaps the most significant feature of Easyweigh’s optical sorter. This sophisticated artificial intelligence system uses deep learning to create comprehensive detection models that identify defects often missed by manual inspection.

The algorithm processes data received from the high-resolution cameras in real time, analyzing factors such as color variations, surface defects (cracks, blemishes, discoloration), and irregularities in shape or size. Over time, the AI model becomes even more accurate as it learns from new data, continuously improving its detection capabilities.

Efficient Ejection Systems for Precise Removal of Defective Tomatoes

As mentioned, the tomato optical sorter’s precise ejection system takes over when defects are detected. It utilizes high-speed air jets or mechanical actuators to remove defective tomatoes from the production line without disrupting the flow of quality products.

The rejection mechanism synchronizes with the AI detection model, ensuring accurate targeting and removal of defective tomatoes. This integration minimizes the risk of accidentally discarding high-quality tomatoes, reducing waste and maximizing yield. Combining high-speed sorting and precise defect removal increases efficiency and supports continuous workflow, making it ideal for large-scale tomato processing operations.

How Optical Sorting Increased Yield by 25%

Integrating Easyweigh’s automatic optical sorting machines into tomato processing lines can help swing a 25% boost in yield. This improvement stems from the machine’s ability to accurately detect defects, reduce product waste, and streamline sorting operations. Since it automates the sorting process, the machines minimize human error, optimize grading, and remove only defective tomatoes.

Below, we explore how it can boost yield by that much.

Enhanced Accuracy and Precision

One of the most significant contributors to the increased yield of sophisticated vision sorting machines is the enhanced accuracy and precision it guarantees. Unlike manual sorting, which is prone to inconsistencies and human error, these machines achieve nearly 100% defect detection. Moreover, their high-resolution cameras and AI capabilities can detect imperfections, such as micro-cracks, discolorations, or subtle ripeness variations.

This precision level ensures the rejection of only tomatoes with defects, preventing unnecessary waste of good produce. Moreover, the AI model has learning functionalities that enable it to adapt and improve its detection capabilities. The result is enhanced sorting accuracy, retaining more marketable tomatoes, directly contributing to the 25% yield increase.

Improved Efficiency and Throughput

Efficiency is another key factor in the yield improvement. Easyweigh’s optical sorting machines are designed for high-speed sorting and can process thousands of tomatoes per hour without compromising accuracy. This rapid sorting speed ensures efficient handling of large product volumes, meeting the demands of high-capacity processing facilities.

In addition, the system supports a continuous workflow, reducing downtime between batches and eliminating bottlenecks. It ensures consistent, optimized grading and product quality. It enables food manufacturers to maximize the number of tomatoes that meet the required standards for different markets or processing needs.

Consistency in Quality Standards

Maintaining consistent quality is crucial in tomato processing, both for consumer satisfaction and regulatory compliance. These advanced optical sorting machines aid in standardizing product quality across batches.

Uniform Products

The machine ensures that all tomatoes leaving the production lines meet predefined standards for size, ripeness, and overall quality. This uniformity is essential for processors supplying retailers, as it enhances product presentation and reduces complaints about inconsistent quality across batches.

Market Readiness

High-quality, uniformly sorted tomatoes are more likely to meet the stringent requirements of retailers and food processors. Therefore, food manufacturers experience fewer rejections at the distribution stage, reducing product returns and associated costs. Moreover, the consistent quality of tomatoes improves customer satisfaction, strengthens brand reputation, and opens up opportunities in premium markets.

What Makes Easyweigh’s Optical Sorting Equipment a Reliable Choice

Easyweigh’s optical sorting equipment‘s advanced technologies and effectiveness make it a reliable choice for businesses looking to enhance productivity, improve product quality, and reduce waste. Therefore, whether in tomato processing or other applications, the machine consistently delivers results that translate to higher yields, reduced operational costs, and superior product quality.

Here’s what makes Easyweigh’s optical sorting equipment a trusted solution in the industry.

Advanced Technology

At the heart of Easyweigh’s optical sorting equipment is cutting-edge technology designed to ensure maximum efficiency and accuracy. As reiterated, Easyweigh’s machines leverage advanced AI algorithms with deep learning capabilities. This technology allows the system to create comprehensive data models, continuously improving sorting accuracy.

In addition, Easyweigh’s optical sorters’ high-speed data processing capabilities enable real-time analysis of products on the production line. Their rapid processing ensures that decisions about each tomato are made within milliseconds, allowing for seamless, high-speed sorting without compromising accuracy.

What’s more? The execution unit activates when it detects defects. This part of the system ensures precise and immediate action, whether ejecting defective tomatoes or directing sorted products to specific categories. The execution unit is engineered for speed and precision, ensuring that good products are not mistaken and prompt removal of defective ones.

Proven Results in Real-world Applications

Besides theoretical narratives, the Easyweigh optical sorting machine has demonstrated proven results in real-world applications. Numerous businesses that have integrated the device into their production lines report significant efficiency, product quality, and yield improvements.

In the case study highlighted in this article, the tomato processing facility experienced a remarkable 25% increase in yield, directly attributed to the machine’s performance. Similar testimonials from other industries, such as food processing and agriculture, reinforce the reliability and versatility of Easyweigh’s technology.

Beyond testimonials, data from real-world operations supports Easyweigh’s claims. Metrics such as defect detection rates, sorting accuracy, throughput speeds, and reduced product waste consistently show substantial improvements after adopting Easyweigh’s solutions. These results highlight the machine’s capability to deliver on its promises. Therefore, the optical sorting machine price is a reliable investment for businesses seeking operational excellence.

Unparalleled Customer Support

One key factor distinguishing Easyweigh from other optical sorting machine manufacturers is its commitment to unparalleled customer support. Easyweigh understands that the value of its equipment extends beyond the point of sale, which is why it offers comprehensive support services to ensure customers get the most out of their machines.

- Installation: Easyweigh provides professional installation services to ensure the equipment is correctly set up and integrated into existing production lines. This added service minimizes downtime and ensures the machine operates at peak efficiency from day one.

- Training: Easyweigh offers quick training programs for operators and maintenance personnel to maximize the benefits of its optical sorters. This training covers the basic operations to advanced troubleshooting, empowering teams to use the equipment effectively and independently.

- Maintenance Services: Regular maintenance is critical to the long-term performance of optical sorting machines. Easyweigh offers responsive maintenance services, including preventive maintenance plans and on-demand technical support. Their prompt customer service ensures minimal downtime in case of technical issues, keeping production lines running smoothly.

Conclusion

Easyweigh’s optical sorting machines have proven to be game-changers in tomato processing. They effectively tackle challenges of inconsistent quality, manual sorting limitations, and production inefficiencies. The machines deliver enhanced accuracy, improved throughput, and consistent product quality by leveraging advanced AI algorithms, high-speed data processing, and precise defect detection.

This case study’s 25% yield increase underscores their impact, while real-world testimonials and comprehensive customer support further validate their reliability. Therefore, businesses seeking to optimize processing operations, reduce waste, and boost productivity can rely on Easyweigh’s optical sorting solutions as a wise investment.