Introduction

Weight sorting machines are pivotal in modern manufacturing and food industries, ensuring efficiency, precision, and compliance with strict quality standards. However, selecting the right machine can be challenging due to the variety of available options, diverse industry requirements, and the need for advanced features to meet growing demands.

This article provides a comprehensive step-by-step guide to help businesses choose the best weight grader machine. From understanding your needs to evaluating features and partnering with trusted manufacturers, this guide simplifies the decision-making process for an optimized investment.

Step 1: Understand Your Business Needs

To select the right weight sorting machine, you must first analyze your business’s specific requirements. A thorough understanding of the products you handle and the operational demands ensures you choose a machine that meets your expectations.

Identify the Type of Products to be Sorted

Weight sorting machines vary in their suitability for different industries. Let the food products are looking to sort guide the device you use. For example, food industries may utilize weight sorters for the following items.

- Seafood: Specialized weight sorter machines like fish weight sorting machines are tailored for delicate handling and high precision.

- Poultry: Machines designed for poultry ensure accurate grading of individual cuts or whole birds.

- Industrial Items: Heavy-duty weight graders handle bulkier or non-food products efficiently.

Identifying the primary product category helps narrow down options to machines optimized for specific needs

Consider Throughput Requirements and Precision Needs

Evaluate the volume of products your business processes daily. Machines with higher throughput rates are essential for large-scale operations. At the same time, precision requirements are critical for industries like food processing, especially in industries where even minor weight variations can impact compliance and customer satisfaction. By understanding these core factors, you can ensure that the chosen weight sorting machine meets production efficiency and quality standards.

Step 2: Explore the Types of Weight Sorting Machines

Understanding the different types of weight grader machines available is crucial for making an informed decision. Each type caters to different industries and specific operational needs. Therefore, you should critically observe easy device, before selecting what best suits your specification.

Overview of Various Kinds of Weight Sorter Machines

As mentioned, weight sorting machines come in various configurations. Below, we explore some common weight grader machines.

- Single-Lane Weight Graders: Ideal for businesses with limited throughput requirements. They provide precise sorting for smaller-scale operations.

- Dual-Lane Weight Graders: These machines, such as Easyweigh’s dual-lane weight grader, are designed for higher efficiency and enable simultaneous sorting of multiple product lines.

- Rotating Tray Weight Graders: Perfect for delicate products like seafood, these machines ensure gentle handling and accurate sorting.

- Automatic Sachet Sorting Machine: Upon configuration, the device device independently sorts bagged products from an irregular stack in an orderly manner.

- Visual Inspection and Weight Grader: This device is a sophisticated fruit sorting machine, equipped with visual weight sorting technology to group products based on programmed information.

Highlight Customized Options for Specific Industries

Sometimes, a generalized weight sorting machine may not suit your business goals, as you may require a customized weight sorting machine. That said, some specific weight grader machines offer customization to address unique industry needs. Below, we explore specific industries that may have unique weight sorters.

- Food Industry: For example, fish weight sorting machines have material boxes designed to match specific product specifications, ensuring precise sorting.

- Agriculture: Customized weight graders can be adapted to efficiently sort fresh produce or grains.

- Manufacturing: Heavy-duty machines handle industrial hardware or raw materials with tailored configurations.

Customizable solutions ensure the machine seamlessly integrates into your workflow and optimally serves your operational goals.

Step 3: Evaluate Key Features

Selecting the right weight sorting machine involves assessing the features that ensure precision, speed, and operational efficiency. Advanced functionalities can significantly enhance your productivity

Accuracy and Speed of the Weight Sorter

The precision of a weight sorter is crucial in delivering consistent results. Modern weight graders have high-accuracy sensors that minimize deviations and ensure uniform weight distribution. Similarly, speed is essential, particularly in industries with high throughput demands. A machine that combines precision with rapid sorting capabilities reduces bottlenecks and improves overall efficiency.

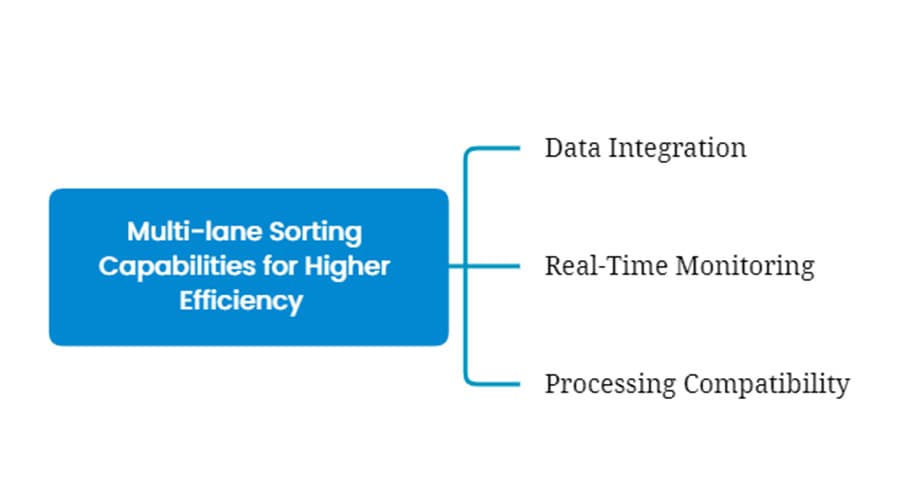

Multi-lane Sorting Capabilities for Higher Efficiency

Multi-lane sorting is a game-changer for operations requiring simultaneous processing of multiple products. Machines like Easyweigh’s dual-lane weight grader exemplify this innovation, offering exceptional performance by doubling the sorting capacity.

In addition to its speed, this weight grader integrates advanced features like:

- Data Integration: Streamlines the collection and analysis of sorting metrics for informed decision-making.

- Real-Time Monitoring: Ensures instant adjustments to maintain accuracy during operation.

- Processing Compatibility: Allows seamless integration with existing systems for smoother workflows.

These features make such machines ideal for businesses aiming to enhance precision and scalability without compromising efficiency.

Step 4: Assess Build Quality and Maintenance Requirements

When choosing a weight sorter machine, the build quality and maintenance demands are key considerations that directly impact long-term efficiency and cost-effectiveness. You want a device built with premium materials for longevity, requiring minimal maintenance needs.

Importance of Durable Materials for Long-lasting Performance

Weight sorting machines often operate in rigorous environments, making durability essential. Therefore, manufacturers require machines constructed with high-quality materials like stainless steel that are resistant to wear, corrosion, and damage from frequent use.

Durable designs ensure consistent performance over extended periods, reducing the need for frequent replacements and repairs. For seafood and poultry processing industries, durability supports hygiene compliance in wet and humid conditions.

Low-maintenance Designs for Reduced Downtime and Costs

Maintenance requirements significantly affect operational efficiency and cost. Modern weight graders, like those offered by Easyweigh, are designed to minimize upkeep with:

- Easy-to-clean surfaces: Essential for food industries to maintain hygiene standards.

- Simplified components: Streamlined designs allow for quick repairs and replacements.

By reducing the frequency of maintenance and associated downtime, businesses can maintain consistent production schedules and save on operational costs.

Step 5: Consider Scalability and Future-Proofing

A weight sorting machine is a long-term investment, and it is crucial to ensure it adapts to evolving business needs and technological advancements. Generally, these machines support easy and seamless integration with other devices in your production lines for enhanced manufacturing operations.

Weight Grader Whether With Upgradeable Configurations for Growing Business Needs or Not

As your business expands, your weight grader should be able to scale with your operations. Look for machines with modular designs that allow for upgrades such as additional lanes or improved sorting capabilities. Easyweigh’s solutions are designed with growth in mind, offering adaptable configurations that cater to increased throughput demands or new product lines without requiring a complete overhaul.

Integration With Advanced Technologies Such as AI and Machine Learning

Future-proofing involves equipping your weight grader with advanced technological compatibility. Modern weight sorting machines integrate with technologies like Artificial Intelligence (AI) and Machine Learning (ML) to enhance efficiency.

For example:

- AI integration can predict maintenance schedules, minimizing downtime.

- Machine learning algorithms improve sorting accuracy over time by analyzing performance data.

Choosing a machine equipped for such advancements ensures your operations stay competitive and meet future industry standards.

Step 6: Partner with a Trusted Manufacturer

Partnering with a reliable manufacturer is pivotal to ensuring your investment in a weight sorter meets your expectations for quality, efficiency, and longevity.

Importance of Selecting a Reliable Supplier Like Easyweigh

Choosing a trusted supplier ensures your weight grader is built to industry standards and tailored to your business requirements. Easyweigh is a leading name in weight sorting solutions, offering a wide range of products for various industries, from seafood to poultry. Our expertise guarantees that your machine is designed for precision, durability, and scalability. Ensure that the manufacturer you partner with prioritizes customer satisfaction by providing transparent processes and pre-sale demonstrations.

Services to Look for: Customization, After-sales Support, and Warranty

When selecting a manufacturer, consider the services they offer beyond the product itself. Our services include:

- Before Sales: We provide our customers with individualized performance testing services. Therefore, you can be rest assured that any equipment you purchase from us will perfectly integrate with your product line..

- After-sales support: Depending on your specific needs, we provide lifetime remote or door-to-door services to our customers. Our facilities also boast adequate spare parts for potential repairs and system upgrade to minimise downtime.

- Warranty: We offer a 1-year warranty and lifetime services. Regardless of your location, be rest assured for prompt reply upon contacting us as a customer. .

By choosing a reputable supplier, you benefit from a trusted partner who supports your business at every stage.

Step 7: Request Demos and Compare Options

Evaluating potential weight sorters thoroughly ensures the machine meets your operational needs. Requesting demonstrations and comparing options helps identify the best fit for your business.

Importance of Testing Machines to Ensure Compatibility With Your Operation

Testing a machine before purchase is critical to ensure it aligns with your production requirements. Easyweigh provides pre-sale test piece testing services, allowing you to see how the weight grader handles your specific products. Once the machine is completed, Easyweigh also supplies a video of the machine testing, demonstrating its performance and capabilities in real time. These measures eliminate uncertainty and offer assurance of the machine’s compatibility and reliability.

Comparing Models Based on Performance, Cost, and Features

Most manufacturers often have various weight grader machines. Therefore, when choosing a device, you need to consider the following factors to make an informed decision:

- Speed and Performance: Evaluate sorting accuracy, speed, and throughput to meet your operational goals.

- Cost: Assess the machine’s initial cost alongside potential savings through improved efficiency and reduced waste.

- Features: Look for advanced functionalities like multi-lane sorting, data integration, and IoT compatibility, which enhance operational scalability and efficiency.

By requesting demos and comparing models, you can make a confident investment that aligns with your business objectives.

Conclusion

Choosing the right weight sorting machine is a critical decision that directly impacts operational efficiency, product quality, and overall business success. You must carefully assess your needs, explore machine types, and evaluate essential features like accuracy, scalability, and durability to find the perfect solution tailored to your industry.

Partnering with a reliable manufacturer like Easyweigh ensures access to high-quality machines, customization, and excellent support services. With the right weight grader, you can streamline operations, reduce waste, and maintain compliance with industry standards, leading your business to long-term success.