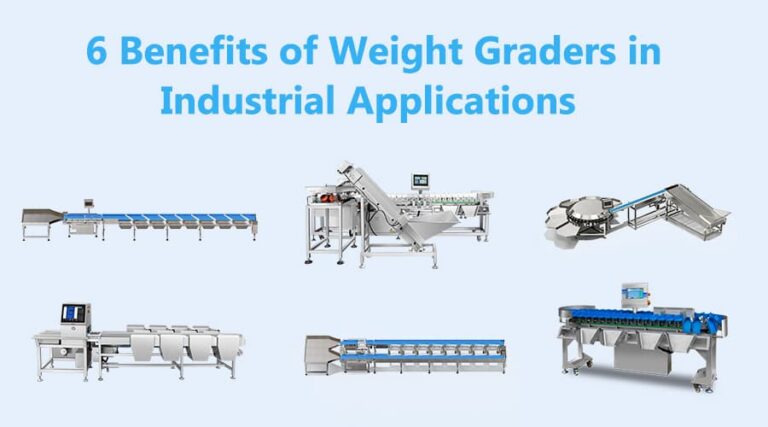

Introduction

Weight sorter machines have recently become a mainstay in food production and manufacturing industries. These advanced machines enhance operational efficiency and offer greater precision in sorting products based on weight.

These weight grader devices automate the sorting process, reducing human error and increasing speed and consistency. These attributes prove essential in elevating operational efficiency, precision, and productivity across various food-related manufacturing and processing sectors. Consequently, many food manufacturers consider weight sorters essential in food production.

This article focuses on the advantages of weight sorting machines, especially their industrial applications. Let’s get straight into them.

Enhanced Precision in Weight Sorting

Weight graders are designed to deliver unparalleled precision in the food sorting processes, ensuring each product meets the required weight specifications. The device integrates advanced technology, ensuring uniformity and eliminating inconsistencies caused by manual sorting. This precision is critical in industries where accuracy affects product quality and compliance with regulations.

The device enhances precision in weighing and sorting through the following:

High-accuracy Sensors Ensure Uniform Product Weights

Weight grader machines are equipped with cutting-edge sensors capable of detecting even the slightest weight discrepancies. These sensors analyze products in real time, allowing consistent, accurate weight measurements. As a result, industries can maintain uniform product weights, enhancing overall quality and meeting customer expectations.

Reduction in Human Error Through Automated Systems

Automation in weight graders drastically minimizes the errors associated with manual operations. Unlike human sorting, which is prone to fatigue and inconsistency, automated systems operate with unwavering accuracy. These systems reduce reliance on manual labor, streamline processes, and ensure high levels of precision in weight sorting tasks.

Increased Operational Efficiency

Weight grader machines significantly enhance productivity by streamlining sorting processes and optimizing workflows. With their ability to handle high volumes of products quickly and accurately, these machines are an essential asset for industries seeking efficiency and reliability.

Faster Sorting Speeds Compared to Manual Processes.

Automated weight graders operate at speeds unmatched by manual sorting methods. For example, the dual-lane weight grader efficiently handles multiple products simultaneously, ensuring faster throughput without compromising accuracy. This innovation allows businesses to meet production deadlines while maintaining quality, making it a valuable tool for high-demand industries.

Optimized Workflow Through Continuous Operations

Again, unlike manual processes that require frequent breaks or adjustments, automated systems like the dual-lane weight grader are designed for continuous operation. They enable seamless product flow, reducing downtime and ensuring consistent output. Moreover, these machines allow food manufacturers and processors to integrate them into their operations, allowing businesses to achieve a streamlined workflow and maximize productivity.

Customization for Diverse Needs

The weight sorter machine is designed to meet the unique requirements of various industries, offering adaptability and precision. Their customizable features make them a valuable solution for businesses dealing with diverse products and operational demands.

Flexibility with Customized Weight Sorting Machines for Specific Products

Weight graders may be tailored to specific product requirements, ensuring optimal performance. For example, customized material boxes can be designed to accommodate products of varying sizes and weights, improving sorting accuracy. These features are particularly beneficial for poultry and fish processing industries, where product specifications differ widely.

Versatility Across Industries

Weight graders are employed in a wide range of industries, demonstrating their adaptability and value:

Food Industry: Fish weight sorting machines ensure accurate grading for fish products, improving processing efficiency and reducing waste.

Agriculture: Rotating trays weight graders assist in sorting fruits and vegetables by size and weight, streamlining packaging operations.

Manufacturing: Machines help classify products like components or packaging materials, optimizing production lines.

Poultry Industry: Customized weight graders enhance poultry sorting and processing by sorting chickens based on size, ensuring uniformity for end products.

Weight graders contribute to enhanced operational efficiency and product quality by delivering precise sorting across sectors across sectors.

Reduced Product Wastage

Weight grading systems are vital in minimizing product wastage, ensuring businesses make the most of their resources while maintaining product quality. By accurately measuring and sorting items, these machines help reduce errors that could lead to discarded products or regulatory violations.

Ensuring Compliance With Weight Regulations

Modern weight graders have precise sensors that ensure products meet industry weight standards. This compliance prevents legal penalties and minimizes overfilling or underfilling, which can lead to significant financial losses. Therefore, using these weight sorters can help businesses remain confident in meeting strict market regulations with minimal waste.

Enhanced Customer Satisfaction by Delivering Consistent Product Quality

Consistency in product quality is key to building customer trust and satisfaction. Weight graders ensure that every item meets predefined specifications, reducing inconsistencies. For example, in food industries, delivering uniformly weighted products, such as poultry portions or packaged goods, fosters a positive customer experience and strengthens brand loyalty.

Data Integration and Scalability

Modern weight grader machines are designed to sort products efficiently and seamlessly into digital ecosystems. These machines leverage advanced data systems to enhance operational visibility, enable scalability, and support long-term growth strategies for businesses across various industries.

Real-time Monitoring and Reporting for Better Decision-making

Weight graders equipped with real-time monitoring capabilities provide instant feedback on operational performance. They generate detailed reports on product weights that help improve sorting accuracy and production output. Therefore, businesses can make more informed decisions to optimize their processes. This data-driven approach minimizes errors, reduces downtime, and boosts productivity.

Compatible With Emerging Technologies Like IoT and AI

Weight sorter machines are increasingly compatible with the Internet of Things (IoT) and Artificial Intelligence (AI) technologies. IoT integration enables remote monitoring and machine adjustments, while AI enhances sorting precision by analyzing large datasets to identify patterns and optimize efficiency.

These advancements ensure the machines remain future-ready and adaptable to industries’ evolving needs. Some devices even integrate visual sorting technology for more enhanced weight sorting. They feature several smart cameras, lighting, and appropriate software to enable them to view and inspect products for visual defects.

Low Maintenance and High Durability

Weight sorting machines are built with robust materials and modern designs, ensuring they require minimal maintenance. Their streamlined construction reduces the need for frequent repairs, saving businesses time and operational costs. In addition, these machines are designed for ease of use, allowing operators to perform basic maintenance tasks effortlessly, further reducing downtime.

Modern Designs Require Minimal Upkeep

The latest weight grader models feature user-friendly interfaces and intelligent diagnostics, which alert operators to potential issues before they lead to breakdowns. This proactive maintenance approach ensures machines remain in peak working condition with minimal intervention, contributing to smoother operations and fewer disruptions in production.

Longevity of Machines Ensures Value for Money

With durable construction and high-quality components, modern weight graders offer exceptional longevity. Their ability to withstand harsh industrial environments and continuous operation translates into excellent return on investment. Consequently, food manufacturers and processors can rely on these machines for years, making them a valuable asset in performance and cost efficiency.

Conclusion

Weight grading machines are revolutionizing operations in multiple industries by ensuring accurate product measurements, minimizing wastage, and enhancing overall efficiency. Their versatility, low maintenance requirements, and ability to integrate with emerging technologies make them an invaluable tool. Many food manufacturers now consider weight grading machines an integral tool that enables them to meet regulatory standards and improve customer satisfaction. Therefore, you should consider investing in these machines to guarantee long-term value and operational success.