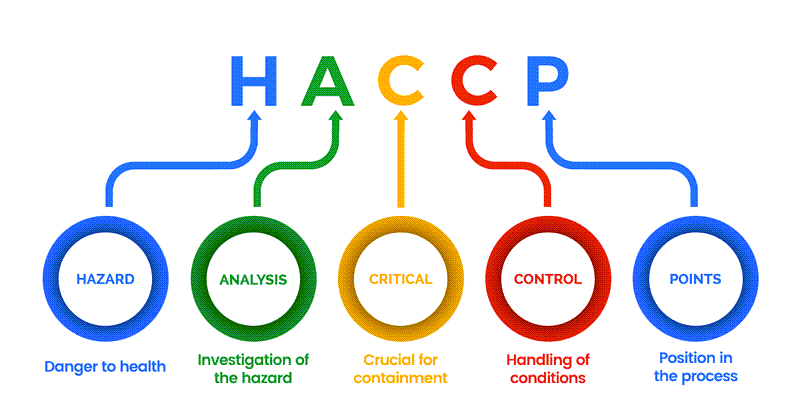

What is HACCP?

Why HACCP Important

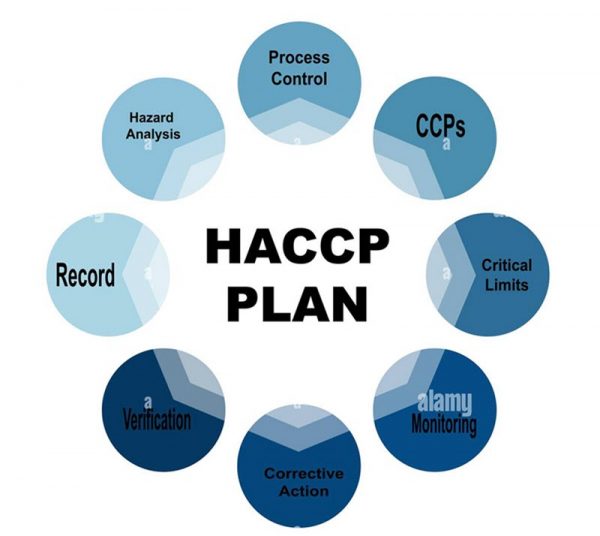

7 Principles of HACCP

1. Conduct a Hazard Analysis

2. Identify Critical Control Points

3. Establish Critical Limits

4. Monitor Critical Control Points

Monitoring each CCP is vital to ensuring that dangers do not exceed the critical limits defined. CCPs are observed in a variety of ways, but some examples include

- Using a probe thermometer to check the temperature of a refrigerator or freezer daily.

- Maintaining bait traps requires regular pest inspections.

- Having employees document specific cleaning methods in the Food Safety Program.

- In many circumstances, food safety legislation requires that all potential dangers be monitored to ensure they do not exceed critical thresholds.

5. Establish Corrective Actions

Food manufacturers must take corrective action if a hazard surpasses its critical limits. Rules must be developed outlining the disciplinary measures to be done if a threat exceeds its limitations. These precautions are taken to ensure no hazard harm surpasses its critical limit.

6. Establish Record-Keeping Procedures

Procedures will be implemented to ensure that all enterprises throughout the food supply chain effectively produce a safe product for humans to consume. The HACCP principles were created to apply to each firm throughout the food manufacturing process. It is the responsibility of the business to guarantee that the HACCP principles have been adapted and implemented.

7. Establish Verification Procedures

According to the HACCP principles, the food manufacturer must preserve complete, up-to-date records. Depending on your business, these records are frequently stored in a live document known as the Food Safety Plan. Examples of forms that your company may need to preserve:

- Temperature graphs and records

- Logs of the storage

- Cleaning routines

- Employee credentials

- Logs of pest control

How to Create HACCP Food Safety Plan

A HACCP plan is a legally binding document that compiles the entire business process flow, hazard evaluation, control measures, and ongoing monitoring activities based on HACCP principles.

Making a HACCP plan necessitates a significant amount of time spent in the office, attending meetings, and reviewing the entire process layout. If necessary, you can employ a food safety specialist.

Creating a HACCP plan is time-consuming and crucial, but you should not be concerned. It may appear to be a lot of work, but your HACCP plan serves a very active, everyday purpose – to keep people coming back to your establishment.

Here’s how to create a HACCP Food Safety Plan.

1.Assemble a HACCP Team

A team of personnel from several departments must be assembled to create a thoroughly documented HACCP strategy. All participants must have detailed knowledge of the processing line. Members must be diverse and committed to developing a successful outcome.

2. Describe the Food and Its Distribution

A HACCP plan must fully disclose your product’s contents, manufacturing method, distribution conditions, and the appropriate packaging materials. Your HACCP plan will specify the temperatures, moisture levels, oxygen availability, and other variables necessary to transport and store nutritious food.

3. Describe the Intended Use and Consumers of the Food

The team can determine the possible danger of introducing improper components to immunocompromised persons such as newborns, the elderly, and pregnant women by identifying the intended customers.

4. Develop a Flow Diagram That Describes the Process

The flow diagram describes the stages involved in creating your product. Making a HACCP plan allows the team to check and identify potential food hazards in each process stage and whether there are successful strategies for controlling them. This also helps the team to design a controllable processing step to avoid danger. The diagram doesn’t need to be professionally created. A standard block-type flow diagram would suffice.

5. Develop A Flow Diagram That Describes the Process

Before implementing HACCP’s fundamental principles, the team must independently validate the flow diagram by conducting an onsite inspection.

How to Meet HACCP Standards

1. Identify all Potential Hazards in Your Firm and Devise Strategies

Your team should analyze all relevant data concerning the product’s safety, such as process performance, quality problems, customer dissatisfaction, internal and third-party audit results, and other relevant information.

Fortunately, there are pieces of equipment you can use to ease the workload. Check out these three options.

First, you can use the Compact Economical X-Ray Inspection System for Small Items FXR-2417K100. This automated x-ray inspection system is appropriate for the pharmaceutical and small packaged goods industries. The machine can not only identify metal, bones, glasses, ceramics, stones, plastic, and rubber but also guarantee product quality by detecting defective items and missing pieces.

Next, there is X-Ray Inspection System for Large Package FXR-9045. This x-ray inspection system uses penetration to identify impurities, including all types of metals, rigid plastic, desiccant, etc.

Lastly, the Combi Metal Detector and Checkweigher FMD-CW-210 can do metal detection and weight testing on the same equipment. This device is commonly utilized in aquatic products, pickled items, vegetables, cosmetics, and the toy industry, among other things.

2. Identify Crucial Control Points to Take Action

2.1 Artificial Contamination

Food tainted at the manual loading stage is hazardous to one’s health. Use the Conveyor Metal Detector FMD-30/40/50 Series to fix this problem. The FMD-30/40/50 Conveyor Metal Detector detects metal contamination during food processing.

2.2 Unpackaged Pre-Stage Contaminants

To increase product quality, use the X-Ray Inspection System for Unpackaged Bulk Products FXR-4017K100S to pick contaminants such as bone, plastics, glass, ceramic, stone, and hard metal.

This x-ray inspection system is widely employed in detecting foreign bodies in agricultural products processing, food processing, pharmaceuticals and other industries.

2.3 Contamination During Transport

Food can also get contaminated during transport to storage and subsequent product processing. With that, select pollutants by penetration, which includes all types of metals (Fe, non-Fe, stainless steel), bones, glass, pottery, stones, sand, rigid plastic, desiccant, and so on.

The X-ray Inspection System for Packaged Products FXR-40/50/60 Series selects pollutants by penetration, which includes all types of metals (Fe, non-Fe, stainless steel), bones, glass, pottery, stones, sand, rigid plastic, desiccant, and so on.

The food x-ray machine can detect foreign bodies in food packaging, medicines, light industries, etc., to ensure everything is OK during producing and packaging.

3. Assemble a Team of Experts

The team’s technical understanding should be sufficient to identify relevant hazards and necessary controls. Team members should also have enough practical knowledge of the process to advise on the practicality of adopting such rules.

4. Monitor All Critical Limits

We must monitor and ensure that each critical point can be controlled within the vital limits. So, our team members should be according to relevant regulations to carry out. They can finish their job better to ensure food safety.

5. Monitor All Skill Types

Each member of the HACCP team must understand their job, have received proper training, and have been granted express authorization by management to engage in the HACCP research effectively.

To meet these requirements, you may find it helpful to establish a HACCP team matrix that summarizes the HACCP team members’ selection, roles, duties, and authorities for each phase.

6. Keep Comprehensive, Up-to-Date Records

The final component of HACCP is keeping records of everything reported. Traceability is vital for later problem resolution and assisting with the evaluation process.

For example, many food manufacturers will keep track of all temperatures they assess, whether for cooked or chilled food. This approach ensures everything functions correctly and serves as a backup in case of any issues.

7. Update Your Food Safety Plan

When monitoring reveals that critical limits at a CCP have been exceeded, corrective action must be performed to ensure that the danger does not become a problem.

It would help if you always were confident that the food you provide your consumers is safe. The only way to be convinced of this is to create and adhere to a food safety plan (FSP). Update your food safety plan as much as necessary.

Conclusion

HACCP can be a complex topic, but it is essential to know about it! Failure to comply with HACCP rules may result in lawsuits and, ultimately, the closure of a food business.

Increasing regulatory and customer demands have put additional pressure on food companies. Food manufacturers should avoid every step of the way where contamination can occur. Manufacturers’ efficiency method is establishing reliable food inspection procedures to ensure product safety and quality.

Knowing that food inspection is an essential procedure. Food manufacturers can employ technologies like food x-ray inspectors or food metal detectors to detect physical impurities and analyze the internal structure of food products for quality objectives.