Introduction

Checkweighers play a crucial role in modern manufacturing, packaging, and quality assurance systems across various industries. compliance with regulations.

A checkweigher system is not merely a basic weighing scale; it is an advanced technology capable of high-speed operations and precise measurements. These systems provide an automated solution for quality checks, making them essential for companies handling large volumes of goods.

In this article, we will explore the types of products that can be weighed using Easyweigh checkweigher, the importance of checkweighing across different industries, and how checkweighing helps ensure compliance, safety, and efficiency. Whether you are involved in the food checkweighing industry or the manufacturing of consumer goods, this article will serve as a comprehensive guide to understanding checkweighers and their applications.

Overview of Check Weigher and Its Key Features

Before exploring the different products that can be weighed, it’s important to understand why inline checkweighers are so effective. These machines are designed for high-speed, precise weight measurement and are equipped with various features that make them suitable for a wide range of applications.

What is a Checkweigher?

A checkweigher is an automated system designed to verify the weight of products as they move through a production or packaging line. Unlike traditional scales that measure weight at a single point in time, checkweighers continuously monitor the weight of products in real time, often at very high speeds.

Inline checkweighers utilize load cells or weigh cells to measure weight by detecting the force exerted by a product placed on them. When a product is weighed, the machine compares its weight to a predefined weight range set by the manufacturer. Products that fall outside the accepted weight range are automatically rejected, ensuring that only those meeting quality standards proceed through the production line.

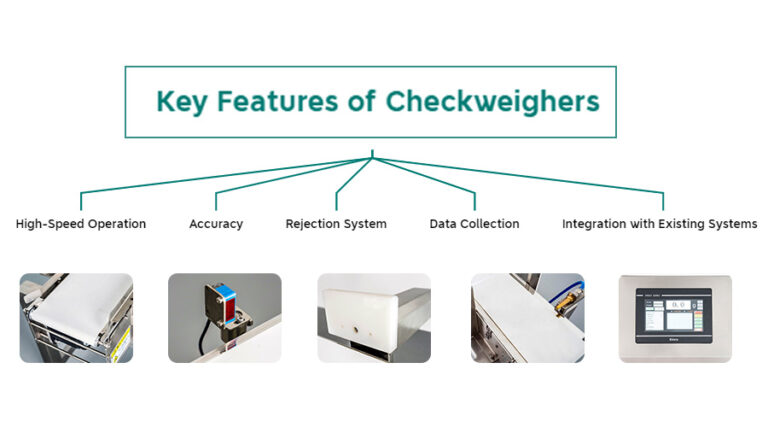

Key Features of Checkweighers

Checkweighers are essential machines in modern manufacturing processes, and they offer several key features:

High-Speed Operation: Check weighers typically operate at speeds up to 1,000 items per minute, depending on the specific machine and product size. This makes them ideal for high-volume production lines.

Accuracy: Modern inline checkweighers provide exceptional precision, often measuring weight to fractions of a gram or milligram. This level of accuracy is crucial in industries like pharmaceuticals and food packaging, where precise weight is vital.

Rejection System: These machines are equipped with various rejection system that automatically divert or remove products that do not meet weight specifications. This feature helps maintain product quality.

Data Collection: Many checkweigher machines come with data logging capabilities, allowing manufacturers to store weight data for quality control, audits, and compliance with regulatory standards.

Integration with Existing Systems: Some checkweighers can be integrated with existing quality control systems, such as metal detectors or X-ray machines. This integration ensures that products are not only within weight standards but also free from contaminants.

Common Applications of Checkweighers in Food Packaging

Food industry manufacturers are among the most significant users of check weighers. In this sector, maintaining precise weight measurements is critical for meeting consumer expectations and complying with regulatory requirements regarding labeling, packaging, and food safety.

Here’s a closer look at the food product types commonly weighed using a checkweigher system.

Packaged and Processed Foods

Check weighing is crucial in packaging processed foods such as frozen meals and snacks to comply with regulatory weight requirements. It ensures that products, like potato chip bags, contain the advertised amount, preventing overfilling, waste, and underfilling, which can lead to customer dissatisfaction and regulatory issues.

Fresh Produce

Checkweighers are essential in packaging fresh fruits and vegetables, ensuring each package, like grapes or apples, meets the correct weight. This process minimizes waste from underfilled packages that can result from improper manual checks.

Beverages

In beverage packaging, checkweigher system ensure bottles, cans, and cartons are filled to the correct liquid volume, adhering to strict regulations. If a checkweigher detects incorrect fill levels, it automatically removes the container from the production line to maintain quality and consistency.

Products like cookies, cakes, and candy bars rely on checkweighers to ensure each package contains the correct weight. This minimizes packaging errors, guaranteeing customers receive exactly what they paid for. For instance, a package of cookies must weigh exactly as stated on the label, and a checkweigher automatically verifies this before sealing and shipping.

Checkweighers systems are vital in the pharmaceutical industry. They ensure precise product weights, which is essential for customer satisfaction and compliance with health and safety regulations.

Tablets and Capsules

Pharmaceutical products like tablets and capsules are weighed with checkweighers to ensure accurate dosages. Even minor weight deviations can significantly impact product efficacy and safety. Using checkweighers, companies confirm that each tablet or capsule falls within the designated weight range.

Liquid Medications

Liquid medications, including syrups and injectable solutions, also require check weighing. Accurate dispensing is crucial; for instance, a checkweigher ensures a bottle of cough syrup has the correct volume, avoiding regulatory issues and health risks.

Medical Devices

In line checkweigher measure medical devices and supplies, such as syringes and diagnostic tools, to meet strict weight specifications for safety and compliance.

Consumer Goods and Industrial Products

Checkweighers play a crucial role not only in the food and pharmaceutical industries but also in consumer goods and industrial sectors.

Personal Care and Household Products

In personal care and household products, such as shampoo and cleaning supplies, in line checkweigher ensure items meet specified weights before packaging. This helps avoid customer complaints and regulatory issues related to product quantity.

Cleaning and Detergents

For industrial cleaning products, accurate weighing is essential for compliance with strict packaging regulations and to maintain product effectiveness.

Industrial Components

Heavy industrial products, such as automotive parts, machinery components, or construction materials, also undergo checkweighing during production. These products are often manufactured in large quantities, and verifying the weight of each item ensures they meet producing specifications.

The Importance of Accuracy in Checkweighing

Accurate weight measurement is crucial across industries, as even small discrepancies can lead to significant problems. Whether in food, pharmaceuticals, or industrial parts, weight accuracy ensures product consistency, regulatory compliance, and consumer trust.

Product Quality: Inaccurate weights can result in customer dissatisfaction, wasted materials, or overfilled products.

Regulatory Compliance: Many industries, particularly food and pharmaceuticals, are subject to strict weight regulations. Accurate checkweighing helps ensure compliance and avoid penalties.

Cost Efficiency: By minimizing product waste and ensuring consistency, checkweighers enable companies to save money and improve production efficiency.

Utilizing a checkweigher ensures that products meet weight specifications, helps maintain high-quality standards and reduces operational costs.

Conclusion

The checkweigher system is an indispensable tool across a wide range of industries. They are crucial in maintaining product quality, ensuring regulation compliance, and improving operational efficiency. Whether you’re working in the food industry, pharmaceuticals, or consumer goods, checkweighing is essential for ensuring the accurate weight of each product, thus avoiding costly errors, reducing waste, and maintaining customer satisfaction.

FAQs

Can checkweighers be used for both small and large products?

Yes, in line checkweighers can be adapted for products of various sizes. Different models can weigh both small items, like individual food packets, and larger, heavier items like large packaged snacks.

What industries use a checkweigher system?

A checkweigher system is used in many industries, including food, pharmaceuticals, personal care products, industrial goods, and packaging.

Do in line checkweighers detect contamination?

Some checkweighers, especially those with metal detector integration, can also detect metal contamination in products, making them suitable for industries where safety is a primary concern, such as food processing.