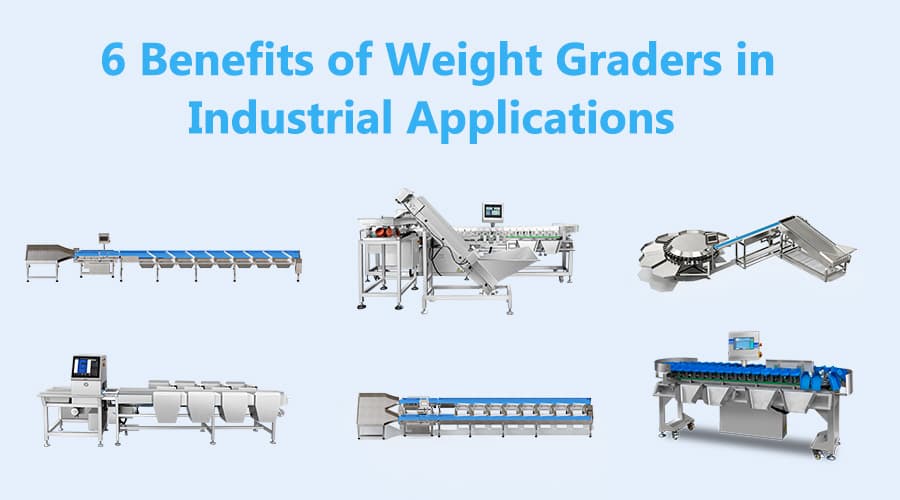

6 Benefits of Weight Graders in Industrial Applications

Introduction Weight sorter machines have recently become a mainstay in food production and manufacturing industries. These advanced machines enhance operational efficiency and offer greater precision in sorting products based on weight. These weight grader devices automate the sorting process, reducing human error and increasing speed and consistency. These attributes prove essential in elevating operational efficiency, […]

6 Benefits of Weight Graders in Industrial Applications Read More »