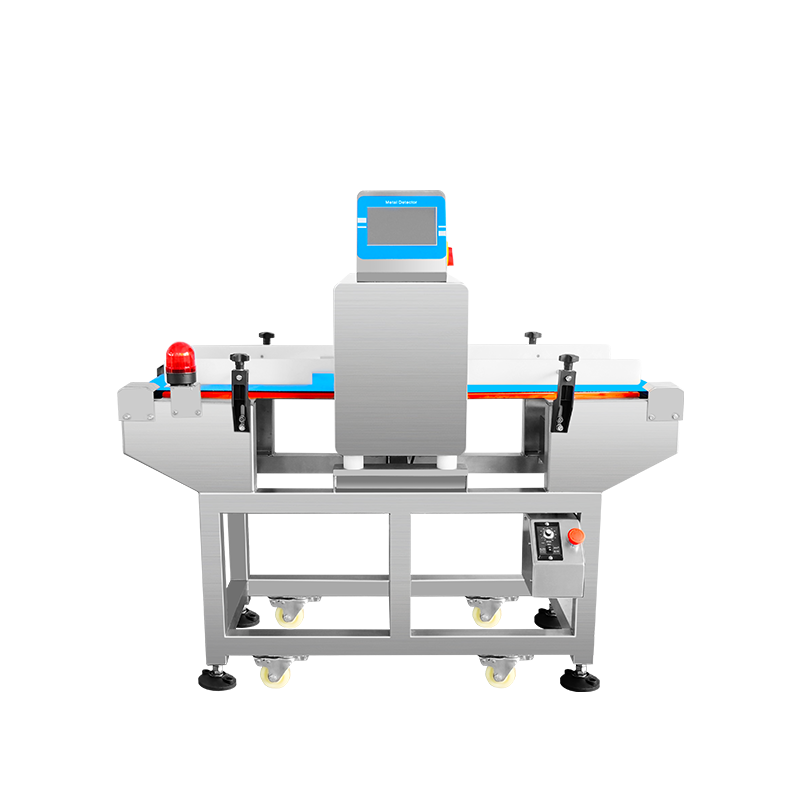

Accurate weighing and detecting are critical in sauce and jam production to uphold product excellence. Checkweighers can reject products that aren’t consistent with setting weight, while x-ray inspection systems and metal detectors identify any foreign materials like glass or metal, guaranteeing product safety.

Embracing these cutting-edge technologies is indispensable in maintaining the highest quality standards and ensuring customer satisfaction in Sauce and jam manufacturing.

Jam

Sauce