Introduction

Food precision and quality control are more important than ever in today’s food industry. Besides detecting contaminants and impurities in food items, fat analysis is now a critical feature food processors need to engage. Therefore, sophisticated X-ray inspection systems are needed to measure accurate fat content, meet global safety standards, and boost consumer trust.

These advanced machines, such as the fat analysis X-ray inspection system, leverage innovative technology to revolutionize fat analysis in various food products, from ground beef to processed meats like sausage and meat pies. They offer unparalleled accuracy and efficiency, enabling producers to maintain compliance and uphold quality.

What is a Fat Analysis X-ray Inspection System?

A fat analysis X-ray inspection system is an advanced food-quality control device designed to measure the fat-to-lean ratio in meat and other food products. This system utilizes cutting-edge X-ray technology to provide non-destructive but accurate analysis, ensuring consistency in product quality and compliance with industry standards. This device is particularly beneficial in sectors like meat processing, where precise fat content is critical for meeting regulatory and consumer expectations.

The Role of Technology in Food Quality Control

Modern food production relies heavily on technological advancements to ensure product consistency, quality, and safety. One such advancement is the use of a fat analyzer for food, which plays a pivotal role in providing precise analysis of fat in food.

Accurate fat analysis provides information for customers looking to meet dietary guidelines. It is also a vital labeling requirement for products intending to hit the world market and ensure customer satisfaction.

Generally, food quality control also allows producers to control costs by optimizing formulations while maintaining desired quality standards. Without these sophisticated systems, errors in fat measurement could lead to regulatory penalties, recalls, or diminished consumer trust.

How Fat Analysis X-ray Inspection Systems Work

The fat analysis X-ray is one of the advantages of using the sophisticated dual-energy X-ray inspection system, which can utilize two energy levels to scan food. The device releases X-ray beams that penetrate the product and measure variations in density, allowing the system to distinguish between fat, lean meat, and other components.

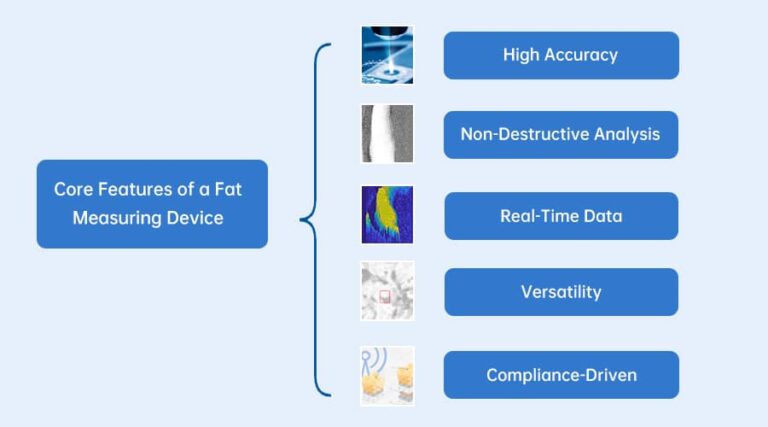

The device then utilizes its advanced algorithms to calculate the fat percentage with high precision, offering quick and reliable results. Below are some of the core features of this x-ray inspection system.

- High Accuracy: The meat fat analyzer X-ray machine delivers precise fat-to-lean ratios, which is critical for meat and processed food production, and detects potential impurities.

- Non-Destructive Analysis: Since it uses X-ray inspection, sample cutting or alteration is unnecessary, preserving the product’s integrity.

- Real-Time Data: Fat analyzers for meat X-ray devices provide instant results for better process control and optimization. Food manufacturers and processors can access the images they provide for better definitive data.

- Versatility: The device suits various foods, including raw meats, sausages, and packaged goods. It detects metals and non-metal contaminants, making it superior to traditional food inspection methods.

- Compliance-Driven: It ensures adherence to food safety and quality standards.

Applications and Benefits of Fat Analysis X-Ray Inspection Systems

Fat analysis X-ray inspection systems are transformative tools in food production, with applications across industries that demand precision and consistency. From evaluating raw meats to analyzing processed foods like sausages and meat pies, this meat fat analyser ensures optimal quality control, compliance with standards, and improved efficiency. Their benefits extend beyond fat analysis, encompassing enhanced food safety, reduced waste, and better customer satisfaction.

Meat Industry: Fat and Lean Content Analysis

Maintaining the ideal fat-to-lean ratio in the meat industry is essential for producing high-quality products that meet regulatory requirements and consumer preferences. In today’s world, people care about their calorie intake, which, if not correctly scrutinized, can significantly increase with fats.

Moreover, there is more health and nutritional awareness now than ever. Therefore, fat analysis X-ray inspection systems enable meat processors to measure fat and lean content accurately. The device ensures consistent product quality that suits customers’ preferences while helping producers optimize their use of raw materials. These systems also help reduce waste by identifying precise cuts and portions, ultimately improving profitability.

Processed and Packaged Meat Foods: Accurate Fat Testing

Fat analysis in food influences taste, texture, and nutritional value in processed and packaged foods like sausages and meat pies. While fat helps enhance tastes, it may become unappealing if it is in excess. Therefore, manufacturers need to invest in sophisticated machines capable of detecting accurate fat analysis, such as a meat texture analyzer or a dual X-ray machine.

These machines, particularly the fat analysis X-ray inspection systems, ensure the accurate measurement of fat. The device allows manufacturers to maintain uniformity in recipes and meet nutritional labeling requirements. By delivering precise results, these systems also help enhance the safety and shelf life of packaged meat products, meeting the expectations of both regulators and consumers.

Key Benefits of Using Fat Analyser Machine

While we have mentioned some of the benefits of X-ray inspection systems, we emphasize some general advantages below.

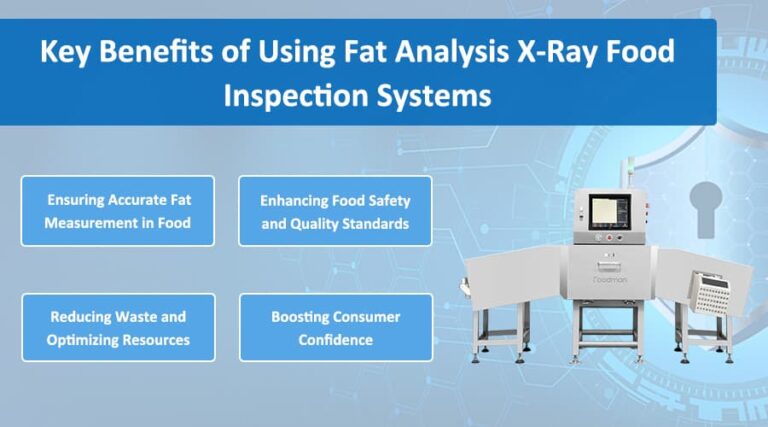

- Ensuring Accurate Fat Measurement in Food: As mentioned earlier, X-ray food inspection systems provide precise information on the food content, including fat contents, which is crucial for maintaining product consistency and meeting dietary regulations. This accuracy helps manufacturers avoid errors in formulations, ensuring that products consistently meet consumer expectations and nutritional standards.

- Enhancing Food Safety and Quality Standards: These systems enhance overall food safety by detecting inconsistencies, impurities, and potential contamination. They play a vital role in adhering to global food safety standards and building trust with consumers and regulatory bodies.

- Reducing Waste and Optimizing Resources: Accurate food analysis helps minimize overuse or underuse of ingredients, reducing waste and cutting costs in production processes.

- Boosting Consumer Confidence: When food quality and nutritional labeling are consistent, customers are more likely to trust and remain loyal to a brand.

Factors to Consider When Choosing a Food X-Ray Machine

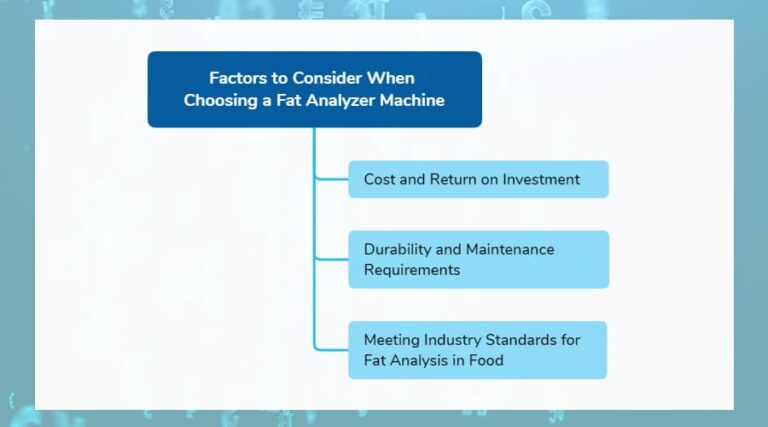

Selecting the appropriate food X-ray machine for food production is a critical decision that impacts quality, efficiency, and compliance. Businesses must consider costs, durability, maintenance, and adherence to industry standards.

While X-ray machines offer better detection capabilities than other inspection systems, like metal detectors, they also differ. For example, the standard X-ray inspection system will struggle to detect calcified bones and fat in meat. Therefore, to maximize this device’s detecting capabilities, you may select a more sophisticated device, such as the dual-energy X-ray inspection machine. Moreover, a carefully selected machine ensures precise analysis and delivers long-term value and reliability.

Below, we explore factors that require consideration before making any selection.

Cost and Return on Investment

Investing in a food X-ray machine may involve significant upfront costs, but the long-term benefits often outweigh these expenses. The machine’s ability to ensure accurate fat analysis and hidden calcified and tiny bones reduces errors, minimizes waste, and improves production efficiency.

Furthermore, it helps maintain precise compliance with industry standards, often preventing costly regulatory penalties and recalls. Therefore, businesses can benefit from the machine, as it helps translate to a solid return on investment through enhanced product quality, operational savings, and customer satisfaction.

Durability and Maintenance Requirements

Durability is crucial for machines operating in demanding food production environments, especially for bulk-volume food manufacturers and processors. Therefore, you need a high-quality food X-ray machine that can withstand rigorous usage while maintaining accuracy.

In addition, regular maintenance is essential to prolong the machine’s lifespan and ensure consistent performance. So, opting for models with user-friendly maintenance features and readily available spare parts can significantly reduce downtime and operational disruptions.

Meeting Industry Standards for Fat Analysis in Food

Compliance with global food safety standards, such as HACCP and FDA regulations, is non-negotiable in the food industry. A reliable fat analysis X-ray machine should meet these standards by providing precise and consistent measurements.

The Fat Analysis X-Ray Inspection System features advanced features like automated reporting, AI-powered algorithms, and self-learning capabilities that help enhance its detection capabilities. Depending on the intended application, the device can also help detect bone, fats, and hard-to-see contaminants, such as functioning as a ground beef fat analyzer.

Moreover, the Meat Fat Analyzer seamlessly integrates with your other compliance systems, simplifying documentation and audits. Machines that adhere to industry-specific standards protect businesses from regulatory risks and enhance consumer trust.

Conclusion

Fat analysis X-ray inspection systems are essential for modern food production. They ensure accurate measurements, enhance quality control, and maintain compliance with industry standards. These machines provide unmatched precision and efficiency, from meat and fish processing to packaged food items.

Therefore, investing in the right fat analyzer machine can help food manufacturers and businesses achieve cost-effectiveness, durability, and superior product quality without compromising evolving regulatory requirements. With innovations like dual-energy X-ray detection and AI-powered features, these systems are shaping the future of food safety and quality assurance, enabling producers to stay ahead in a competitive market.