Introduction

Weight sorting machines have become important devices in various industries, particularly food processing. They ensure that products meet specific weight and quality standards, improving efficiency and reducing waste. Since they automate the weight grading process, weight sorters enhance product consistency and quality, which is vital for maintaining consumer trust and meeting regulatory requirements.

This article explores the diverse applications of weight sorting machines across various sectors. Read ahead!

Overview of Weight Sorting Machines

Weight sorting machines, also known as weight graders or sorters, refer to automated systems designed to categorize products based on weight. These machines use advanced sensors and detection technologies to measure the weight of individual items as they pass through their conveyor belt. Depending on the weight measurements, products are directed into specific categories, ensuring uniformity and accuracy.

Historical Development and Evolution

The development of weight sorting machines has been closely tied to advancements in technology and automation. Early weight sorting methods relied heavily on manual labor, which was time-consuming and error-prone. The introduction of mechanical sorting devices marked the first significant shift towards automation, though these early machines were not accurate enough.

As technologies advanced, weight sorting machines became more sophisticated, incorporating electronic sensors, digital control systems, and software algorithms. These innovations improved weight sorting processes’ precision, speed, and reliability. Today, modern weight sorting machines are equipped with advanced technologies. This includes high-resolution sensors, machine vision systems, and data analytics capabilities, enabling them to handle a wide range of products with exceptional accuracy and efficiency.

The evolution of weight sorting machines reflects the growing demand for high-quality, standardized products across various industries. Without much ado, let’s proceed to the article’s main content – specific applications of weight sorting machines across different sectors.

Seafood Industry

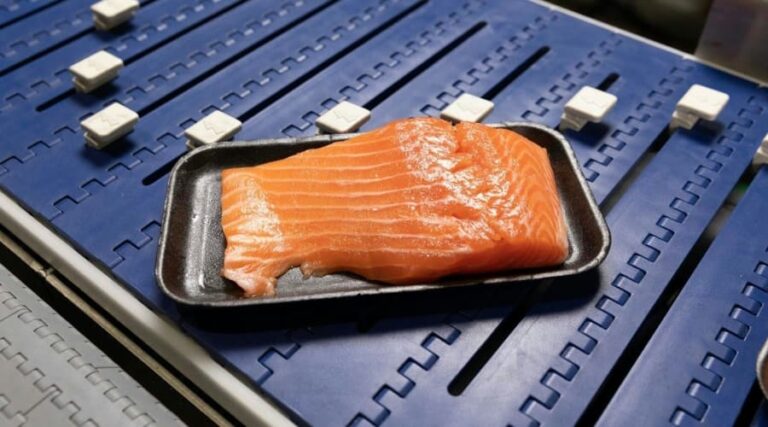

The seafood industry has various products that require weight sorting and grading. These include fish, lobsters, and tuna. Grading these food items helps in pricing and maintaining quality in the market.

Manufacturers of seafood products, like fish and shellfish, must classify and grade each product. Weight consistency is especially important for high-value seafood products like lobster and tuna, where precise grading can significantly impact market value and consumer satisfaction. It is often a hallmark of product quality.

Below, we discuss how a fish sorting machine can benefit the seafood industry.

Ensuring Size and Weight Consistency

Seafood and fish sorting machines ensure size and weight consistency in the industry, which is crucial for maintaining product quality and meeting market demands. Weight sorting machines, such as the EasyWeigh dual-lane weight grader, accurately measure and sort fish, shellfish, lobster, and tuna based on weight and size. This process helps standardize products, making it easier for wholesalers and retailers to manage inventory and pricing.

Meeting Market Standards

Market standards for seafood often include strict size, weight, and quality requirements. Weight sorters help seafood processors meet these standards by automatically categorizing products according to predefined criteria.

For instance, tuna fish grading involves sorting the fish into specific weight categories, which can determine pricing tiers in the market. By adhering to these standards, seafood companies can ensure compliance with industry regulations while enhancing reputation and competitiveness.

Processing and Packaging

Processing and packaging are vital in the seafood industry, where weight sorting machines are crucial. These machines streamline operations, ensuring products are efficiently processed and packaged according to weight specifications.

Enhancing Efficiency

Weight sorting machines significantly enhance the efficiency of seafood processing and packaging operations. These machines can handle large volumes of products quickly and accurately, reducing the time and labor required for manual sorting. This increased efficiency speeds up the processing line and allows companies to meet high demand during peak seasons. For example, the visual inspection and weight grader can assess visual appearance for possible defects while also ensuring it confers with pre-defined weight. This combined feature makes it an excellent fit for enhancing the efficiency of seafood processing and packaging.

Reducing Waste

Waste reduction is a critical concern in the food industry. Weight sorters help minimize waste by accurately sorting products and identifying any that do not meet the required standards. Companies can reduce the amount of discarded or downgraded seafood by ensuring that only suitable products proceed to the packaging stage. In addition, precise sorting helps better utilize raw materials, maximizing yield from each batch of seafood.

Food Industry

Weight sorting machines are a mainstay in the food industry, providing essential support in various sectors, including meat and poultry processing and fruit and vegetable sorting. These machines ensure consistent product quality, compliance with health regulations, and efficient sorting processes.

Since the device is automated, it helps maintain industry standards and enhance operational efficiency across food products.

Food manufacturers use weight graders to sort meat and poultry products into different weight classes during sorting. This includes steak sorting, lamb grading, pork, whole chicken, whole duck, chicken feet, and chicken wings. As mentioned earlier, this sorting is important in pricing and enhancing customer acceptance.

Below, we examine how the food industry benefits from this machine.

Ensuring Consistent Product Quality

Maintaining consistent product quality is essential for consumer satisfaction and brand reputation in meat and poultry processing. Weight sorting machines aid this process by precisely sorting items based on weight, such as steak, pork, chicken, duck, etc. This ensures that each package contains products of uniform size and weight, which is important for retail presentation and cooking consistency. For example, companies can use a single-lane weight grader to accurately portion products, reducing variations and ensuring customers receive exactly what they expect.

Compliance with Health Regulations

The food industry, including those focused on meat and poultry, must comply with health regulations to ensure the safety of their customers and the general public. Weight sorters help these companies adhere to these regulations by ensuring that products meet specific standards for weight and packaging.

Accurate weight measurements are necessary for labeling requirements, portion control, and providing nutritional information. Moreover, weight sorting machines can assist in segregating products that may not meet safety standards, such as undersized or oversized items that could indicate quality or safety issues.

Fruits and vegetables, such as cucumbers, apples, durian, and potatoes, also require accurate weight grading for better pricing and packaging. Let’s examine the role of the weight sorting machine in fruit and vegetable sorting.

Enhancing Product Quality

Appearance and size are critical factors influencing customers’ classification of the quality of fruits and veggies. The weight sorting machine helps enhance product quality by sorting fruits into weight and size categories. This sorting process ensures uniformity in each package, which is important for consumer appeal and shelf presentation. In addition, advanced sorting machines incorporate visual inspection capabilities to detect and remove damaged or blemished produce, further improving overall product quality.

Reducing Waste

Reducing fruit and vegetable processing waste is crucial for cost efficiency and sustainability. Weight sorting machines help minimize waste by accurately sorting and categorizing produce, ensuring that only items meeting quality and weight specifications are packaged and sold. This reduces the likelihood of discarding products that do not meet standards later in the supply chain. Moreover, by precisely sorting produce, companies can optimize the use of resources and minimize losses, leading to better yield management and reduced environmental impact.

Medicinal Materials

Weight sorting machines also offer applications in sorting medicinal materials like ginseng, American ginseng, and Chinese angelica. Here is how the machine helps.

Accurate Portion Control

Precise weight is integral for the effectiveness and safety of medicinal materials. Therefore, accurate portion control is essential in processing medicinal materials, such as American ginseng and Chinese angelica. The weight sorting machine ensures that each portion meets the precise weight specifications required for medicinal products. This accuracy is critical for dosage consistency and efficacy, as even small deviations in weight can affect the potency and effectiveness of herbal medicines. Weight sorters help achieve consistent portion sizes, vital for maintaining product quality and safety standards.

Streamlining Production

Weight sorting machines streamline the production process for medicinal materials by automating the sorting and grading process. This automation reduces the need for manual labor, increases processing speed, and enhances efficiency. These machines help ensure that production lines operate smoothly and without delays.

Agriculture

Agriculture benefits significantly from weight grader machines, particularly in handling products like egg yolks, dates, grains, and seeds. These devices, such as a tomato sorting machine help ensure quality assurance and facilitate precise sorting.

Egg Yolk Sorting

Weight sorting machines are essential in agricultural processing, particularly in sorting specialized products like egg yolks and dates. These machines help ensure accurate grading and categorizing of product weights, facilitating efficient processing and packaging.

In the agricultural sector, sorting specialized products like egg yolks and dates requires precision and care to ensure quality and consistency. For example, companies can use specialized machines like the Disc Type Egg Yolk Sorting Machine for egg yolk sorting.

Grain and Seed Sorting

Grain and seed sorting involves grading products by weight, ensuring uniformity and quality. Weight sorters streamline this process, improving storage efficiency and quality assurance.

Enhancing Storage Efficiency

Proper sorting is critical for optimizing storage efficiency in grain and seed processing. Weight sorting machines help categorize grains and seeds by weight, ensuring uniformity in size and quality. This sorting process simplifies storage by grouping similar products, making managing inventory easier and reducing space requirements.

Accurate sorting also helps prevent spoilage and pest infestations, as uniform products are less likely to experience uneven drying or contamination. For example, companies can precisely sort and detect impurities using advanced technologies like color sorters and food X-ray inspection systems for unpackaged bulk products, enhancing stored grains’ overall quality and safety.

Quality Assurance

Quality assurance is a priority in agriculture, particularly for products like grains and seeds, often used in food production and animal feed. The weight grader machine ensures that only high-quality products reach the market. By accurately sorting grains and seeds based on weight and detecting foreign materials or defects, these machines help maintain stringent quality standards.

Conclusion

Weight sorting machines offer significant applications across various industries. They aid in precise product categorization and enhance quality assurance. Their ability to automate the sorting process improves operational efficiency, reduces waste, and ensures compliance with industry standards.

These machines continue to evolve as technology advances, offering even greater accuracy and versatility. The widespread adoption of weight sorting technology indicates its critical role in modern manufacturing and processing, providing food manufacturers with the tools to meet market demands and ensure product quality.