Introduction

Metal detectors are devices customized for detecting the presence of metals in an area or object. Whether or not these devices, including the best metal detector, can detect metals through obstructions like rubber is a common bothersome question. This article explores the basics of metal detection, metal detectors’ operations, and other vital details about the gadget. Read ahead!

Basics of Metal Detection

Metal detectors are an exciting device that helps detect metals in the earth, surface, or manufactured products. So what’s a good metal detector? This piece of tech benefits the inspection of various products, particularly in pharmaceuticals and food manufacturing. The device helps to ensure that their products are devoid of metallic impurities and contaminants.

This section focuses on the intricacies of this device.

How Metal Detectors Work

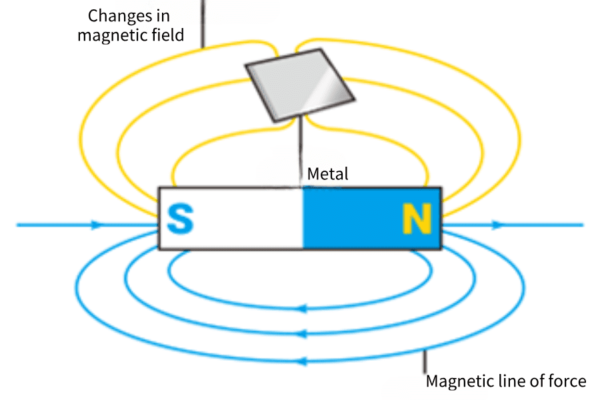

Generally, metal detectors work on the scientific principle of electromagnetism and how the (metallic) object interacts with the electromagnetic field. The metal detectors generate and transmit electromagnetic fields from their coils. When this dispersed field detects the presence of a metallic substance, it energizes it, distorting the original electromagnetic field.

The energized metal creates a secondary field of its own that the coil can detect. The device then turns this secondary field to electrical responses, generating a signal, which could be audio – an alarm – or a visual display to alert the operator of the presence of metal.

However, we must include that many metal detectors have specific features that allow them to distinguish one metal from another. This allows the operator to focus on particular objects and ignore unwanted ones.

Types of Metals Detected

Because metal detectors operate on the principle of electromagnetism, many assume they only detect ferrous or magnetic metals. However, that is not the case. The device detects various metals, including ferrous and non-ferrous metals. Therefore, it can detect metals like copper, lead, zinc, aluminum, gold, brass, silver, tin, bronze, and iron.

Beyond the kind of metal this device detects, a primary detail to consider is how these metals react to the transmitted electromagnetic signal. While the magnetic properties of the metal may not be the bone of contention, the ability to conduct electricity is. For example, metals like titanium and stainless steel that aren’t good conductors are often challenging to locate. On the other hand, good conductors like aluminum and zinc are easily detectable by this device.

This feature makes detecting materials like paper, stone, rubber, bones, and even gemstones challenging to detect by this device.

Limitations in Traditional Detection

Metal detectors prove to be a beneficial innovation, allowing the detection of metallic objects, even when present as contaminants. However, they face some limitations, which include the following.

- Inability to Detect Non-metals: This is the main limitation of traditional detection. Metal detectors find it challenging to detect materials that cannot conduct electricity.

- Difficulty in Discriminating Metals: traditional metal detectors find distinguishing different metals in a mixed environment challenging. This may lead to false signals or even missing the target metal.

- Interference From Surroundings: compromised environments like mineralized soils may interfere with the electromagnetic signals generated by the coils, resulting in false results.

- Difficulty Detecting Through Certain Materials: Metal detectors may experience some difficulty detecting the presence of metals, especially when shielded or enclosed in containers made of densely packed rubber or plastic.

- Inability to Detect Metal Underwater: The presence of water in the environment interferes with the metal-detecting features of traditional metal detectors. Therefore, there is a need to create metal detectors waterproof for these purposes.

.

The Challenge of Detecting Metal Through Rubber

Because rubbers are an insulating agent, detecting metals poses particular challenges for metal detectors. Therefore, manufacturing companies must understand these challenges so they do not get false readings when checking for a metallic object enclosed in a rubber container.

Electromagnetic Fields and Rubber

As we mentioned earlier, since rubber is an insulator, it inhibits the effective transmission of electromagnetic fields transmitted by metal detectors. The rubber shields the amount of field that gets to the metal through absorption and dispersion, reducing effective interaction with the metal. Therefore, it reduces the detector’s ability to accurately detect the presence of metals enclosed in rubber containers, especially when the rubber enclosure is thick.

Factors Affecting Metal Detection Through Rubber

Ideally, it is difficult for metal detectors to detect metals concealed in rubber effectively. However, below is a concise overview of the factors that may improve or diminish the effectiveness of metal detection through rubber.

- The Thickness of the Rubber: The thicker the rubber enclosure, the more difficult it is for the metal detector to detect any metal object it conceals. The thick rubber casing can absorb part of the electromagnetic energy, reducing the amount that penetrates, reaching the metallic object. Therefore, it may result in false results.

- Metal Size and Type: Since the rubber conceals the metal components, the size and type may also affect whether it will be detected. The smaller the metal structure, the less likely it is to be caught. Also, non-ferrous metals will generally produce weaker signals, limiting detection accuracy.

- Metal Detector’s Frequency: Increasing the detector’s frequency will improve its activity, enhancing the chances of metal detection through rubber.

- The Detector’s Sensitivity: Another way to improve the detector’s functions is to fine-tune its sensitivity. Or, if you notice that your metal detector has a low sensitivity, you may need to switch to a more sensitive one to increase the chances of metal detection through rubber.

Historical Challenges and Advancements

Metal detectors were initially used to detect metals underground – mostly ornamentals and treasures hidden under the soil. However, these instruments were primitive and often limited and unreliable, providing archaeologists and treasure hunters with false alarms. Detecting metals, such as rubber, through enclosures took a lot of work. Therefore, there is a need to modify and improve them.

Over the years, this device has received significant innovations, making it more reliable and increasing its penetration power, including through rubber. Some of the advancements include

- Improved coil designs

- Enhanced electromagnetic signal generation and receiving

- Optimized signal processing algorithms

- Increased sensitivity and frequencies, etc.

The development of advanced algorithms has made analyzing signals more effective, reducing the chances of false positive alarms and increasing the accuracy of the metal detector. Today, metal detectors can detect through rubber, particularly after fine-tuning its sensitivity. Food metal detectors are also used to identify metal contaminants.

How Do I Improve the Metal Detecting Power of My Detector?

Improving the metal-detecting power of your detector requires you to modify some of the settings. Also, you should perform routine maintenance to ensure the sensor is in optimum condition for the device to function effectively.

Below, we discuss possible options to help you enhance your metal detector’s detecting power.

Sensitivity Setting

First, read the user manual of your metal detector and familiarize yourself with the sensitivity settings. Many people do not read the user’s manual of any gadget they acquire, believing they can figure everything out. Well, it’s only sometimes the case; the manual provides more info on the device, especially those about the model you use.

Therefore, reading the manual, particularly the area that talks about sensitivity, may prove effective for increasing the detector’s power. The metal detector’s sensitivity is what controls the device’s ability. Enhancing the settings will allow it to detect weaker signals, such as detecting meals through rubber.

Modifying the settings also involves adjusting the frequency, modes, degree of search, target volume, and discrimination, among other settings on your device. For example, you may need to balance out or reduce sensitivity. Elevating it for superficial or surface detection may result in false alarms, as it’ll pick almost insignificant signals, such as mineralized soil.

Routine Calibration

As we mentioned earlier, engaging in regular maintenance checks is an effective practice to optimize the device’s detection power. A simple exercise such as regular calibration may ensure your metal detector functions optimally. This may include consistent verification that all components are in good working condition.

Also, you may need to recalibrate the sensitivity, including toggling with the detector and toning it for different environmental conditions, just to ensure full functioning. Again, you shouldn’t forget to adhere to the manufacturer’s guidelines. In fact, if you check through, you’ll see where they recommended you engage in routine calibration to ensure the device’s consistency and accuracy are maintained.

After Epoxy Pouring, Increase the Resting Time

Epoxy pouring is a standard maintenance practice for enhancing metal detectors’ sensitivity. It helps to secure and protect the coils and other electronic components while also serving as a surface finish, improving its appearance. The resin helps stabilize and shield sensitive parts from external elements.

After epoxy pouring, we recommend increasing the metal detector’s resting time. Allow the epoxy to cure and settle, effectively serving as a protective layer. The resin coating it provides contributes to the durability of the metal detector, as it serves as a shield for the sensitive components.

Also, we must mention that using the metal detector immediately after epoxy pouring may expose it to potential damage. It’s best to increase the resting time before using the gadget.

Types of Metal Detectors

Various metal detectors are used in different industries. However, this section will focus on two types with vast functionalities.

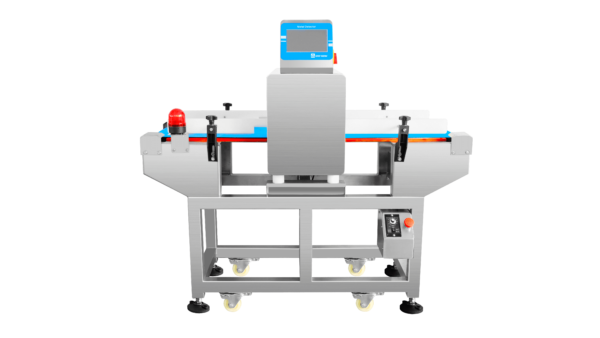

Conveyor Metal Detector

Conveyor metal detectors are a common one in industrial settings. They are mainly for ensuring the quality and safety of products during the manufacturing process. As the name suggests, the metal detector is integrated into a conveyor system. The device possesses intelligent learning capabilities, ensuring easy control and smooth running.

Therefore, operators find using the device for food, pharmaceutical, and other product inspection easy, even without technical know-how. Conveyor metal detectors use advanced electromagnetic field technology to ID and alert operators to the presence of metal contaminants in the detecting material. Also, they support customized settings. This feature proves to help ensure quality control in these manufacturing industries where safety and product integrity are crucial.

Combi Metal Detector and Checkweigher

As the name indicates, a combo metal detector and checkweigher is a more sophisticated device than the conveyor type. The device combines the routine functions of typical metal detection and weight-checking capabilities. Therefore, besides detecting metal impurities, industries can use it for weight verification.

Combo Metal Detector and Checkweigher offer high-quality services in the food and pharmaceutical industries. They provide premium quality control services, as operators can use them to mark out products with metal impurities and those outside the weight limit. This proves effective for speeding up production lines, reducing the need for manual labor, and making adhering to industry standards a lot easier. Moreover, they are also intelligent machines, requiring no significant skill before operating them.

FAQs

Q: Can All Metal Detectors Detect Through Rubber?

A: No. Not all metal detectors can detect metals through rubber. A metal detector must operate at a higher frequency and sensitivity setting to detect metals through rubber. Using basic models to detect metals through rubber enclosures, mainly when it is thick, may prove to be abortive. Therefore, you may need a more sophisticated or specialized metal detector.

Q: How Does Temperature Affect Metal Detection Through Rubber?

A: Temperature may play a crucial role in the activity of metal detectors detecting metallic components through rubber. The increase or decrease in temperature may affect the properties of rubber, further enhancing or limiting possible detection of metal enclosed by rubber. Rubber becomes more rigid at colder temperatures, increasing the detector’s difficulty in detecting metals. On the other hand, the increased temperature may cause the rubber to be more elastic, soften, and expand, allowing for easy transmission of electromagnetic signals for eventual metal detection.

Q: Are There Specific Types Of Metal More Challenging To Detect Through Rubber?

A: Yes, specific metal types are more difficult for metal detectors to detect and talk less of when concealed by rubber. Non-ferrous metals, for example, or smaller objects, are usually more challenging to detect, especially at standard detector sensitivity settings. The same applies to metals with low conductive properties. In either case, you may need to enhance the signal settings or increase the detecting frequency to improve the chances of metal detection through rubber.

Conclusion

While it may be challenging for metal detectors to detect metal through rubber, it is not impossible. The high-end metal detectors are equipped to operate at higher frequencies and sensitivities, and rubber enclosures cannot limit their detecting power. Therefore, the operator must tune the device’s sensitivity and modify the calibration to detect metals. However, simple metal detectors may still be unable to detect metals through rubber enclosures.