Introduction

X ray inspection machine in food inspection refer to advanced technological systems. It’s designed to ensure the safety and quality of consumables. Food x ray machine utilize X-ray technology to scan and inspect various food products. To identify contaminants and foreign objects that may compromise food safety.

Over the years, X-ray inspection system has witnessed a significant surge in adoption within the food processing industry. Its effectiveness in detecting contaminants, ensuring product integrity. Many people use it in the food supply chain to maintain food safety standards.

I. The X-Ray Machine in Food Industry Inspection

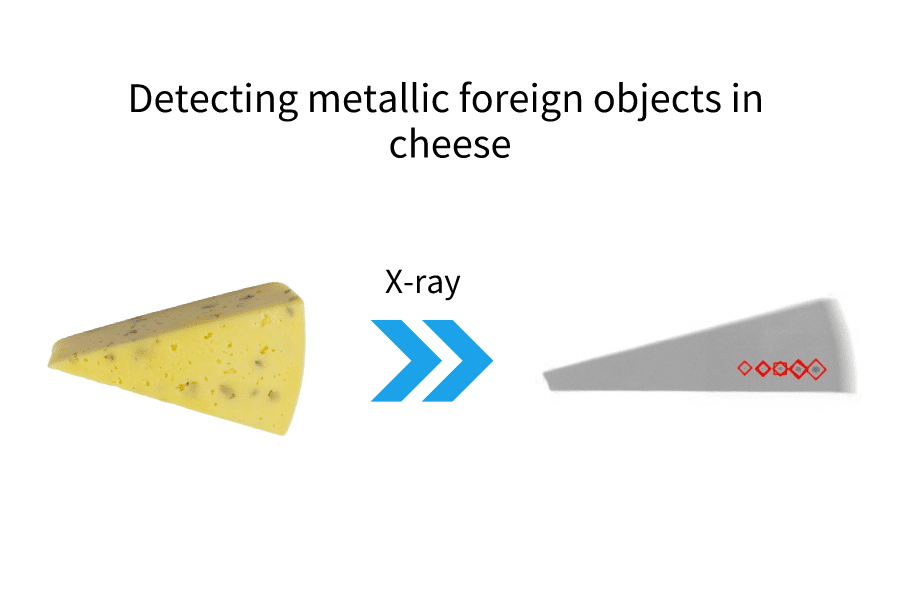

A. How Food X-Ray Machines Work in Food Inspection

Food X-ray machines release a controlled amount of X-ray radiation through food products. These rays penetrate the items and produce an image by detecting the varying densities of different materials. The resulting image enables inspectors to identify foreign objects, defects, and inconsistencies that may be present in the food.

B. Benefits of X-Ray Inspection for Food Safety

Enhanced Contaminant Detection: X-ray inspection systems can detect a wide range of contaminants, including metal, glass, plastic, and even dense bone fragments, ensuring thorough inspection and removal of tainted products.

Increased Production Efficiency: Food X-ray machine enables swift and accurate identification of defects, reducing the likelihood of contaminated products reaching consumers. This contributes to streamlined production processes and improved overall efficiency.

II. Concerns About Food Safety

A. Public Perception and Misconceptions

Despite the proven effectiveness of X-ray inspection system in enhancing food safety, there exists a degree of skepticism and misconceptions among the general public. Addressing these concerns is crucial to fostering greater acceptance and understanding of this technology.

B. Common Myths Surrounding X-Ray and Food Contamination

Myth: X-ray radiation remains in the food.

Clarification:

It is imperative to clarify that X-ray inspection systems employ minimal radiation, and the process leaves no residual radiation in the food. This method is inherently safe and non-intrusive, adhering to stringent safety standards to ensure consumer well-being.

Myth: X-ray technology alters the taste and quality of food.

Clarification:

It is essential to emphasize that X-ray inspection exerts no influence on the taste, nutritional value, or overall quality of food products.

The technology is specifically designed to identify contaminants without introducing any changes to the sensory attributes or nutritional composition of the food. Rigorous scientific studies support this clarification, affirming that X-ray inspection serves as a reliable tool for enhancing food safety without compromising the intrinsic qualities of the consumables.

In essence, dispelling these myths contributes to a more informed public perception, promoting confidence in the application of X-ray technology for ensuring the safety and quality of our food supply.

C. Understanding Radiation Levels in X-Ray Inspection

It’s essential to comprehend that the radiation levels used in X-ray inspection are carefully regulated to ensure they are within safe limits set by international standards and health organizations.

III. Regulatory Standards and Guidelines

A. FDA and International Regulations

X-ray food inspection systems are subject to stringent regulations imposed by authoritative bodies, including the FDA (Food and Drug Administration) and International Regulations such as HACCP. Compliance with these rigorous standards is paramount to ensuring the safety and quality of food products.

The FDA and other regulators create rules for safe and effective X-ray machines in the food industry. These guidelines provide a framework that ensures the safety of consumers by safeguarding them against potential hazards.

B. Compliance Requirements for X-Ray Food Inspection

Manufacturers and operators of X-ray inspection systems must adhere to strict compliance requirements, including regular calibration, maintenance, and documentation. This ensures that the equipment consistently meets the necessary safety and performance standards.

IV. Studies on X-Ray Impact on Nutrients

A. Existing Research on Nutrient Retention

Research conducted by esteemed researchers around the globe has provided a resounding consensus on the nutritional content of various food items. This collective body of research has consistently reaffirmed that the X-ray inspection system has minimal to no effect on the retention of essential nutrients in food. The studies span diverse food categories and employ rigorous methodologies. These also have demonstrated that essential nutrients in food remain intact even after exposure to an X-ray inspection system.

Numerous studies, spanning diverse food categories and employing rigorous methodologies, have consistently reaffirmed the nutritional integrity of items subjected to X-ray inspection system. Researchers have delved into the impact on essential vitamins, such as vitamin C, vitamin A, and B-complex vitamins, elucidating the technology’s negligible influence on these micronutrients. Similarly, a detailed exploration of essential minerals, including calcium, iron, and potassium, has revealed that X-ray inspection does not result in significant alterations to the mineral content of food.

Furthermore, the analysis extends to macronutrients—proteins, fats, and carbohydrates—which form the foundation of our dietary requirements. The comprehensive findings indicate that X-ray technology preserves the macronutrient profile of food, ensuring that the energy-providing and essential building blocks remain unaffected.

In essence, the culmination of these studies underscores that X-ray inspection system stands as a reliable method for upholding food safety without compromising the nutritional quality of our consumables. This robust consensus, derived from meticulous research across various nutritional components, contributes significantly to dispelling concerns and instilling confidence in the application of X-ray technology within the food industry.

B. Effect of X-Ray on Different Packaging Materials

X-ray inspection is versatile and can accommodate various packaging materials without compromising its effectiveness. Whether it’s metal, plastic, or paper packaging, X-ray machines can penetrate and examine the contents inside, ensuring a thorough inspection across different packaging types.

Conclusion

In conclusion, X-ray machines play a crucial role in upholding food safety standards by providing an efficient and non-intrusive method for inspecting food products. Understanding the technology, debunking myths, and adhering to regulatory guidelines are key to fostering trust in the use of X-ray inspection systems within the food industry.

FAQs

Q1: Does X-ray inspection leave any radiation in the food?

A1: No, X-ray inspection systems use a controlled amount of radiation, and the process leaves no residual radiation in the food. It is a safe and non-intrusive method designed to enhance food safety.

Q2: Can X-ray technology alter the taste and quality of food?

A2: No, X-ray inspection has no impact on the taste, nutritional value, or overall quality of food products. The technology is specifically designed to identify contaminants without affecting the sensory attributes of the food.

Q3: How does X-ray inspection affect the nutrients in food?

A3: Scientific studies have consistently demonstrated that X-ray inspection has minimal to no effect on the retention of essential nutrients in food items. The technology is focused on detecting contaminants and foreign objects while preserving the nutritional integrity of the products.